300 novelties

to fully satisfy you

LEAN tools and approaches

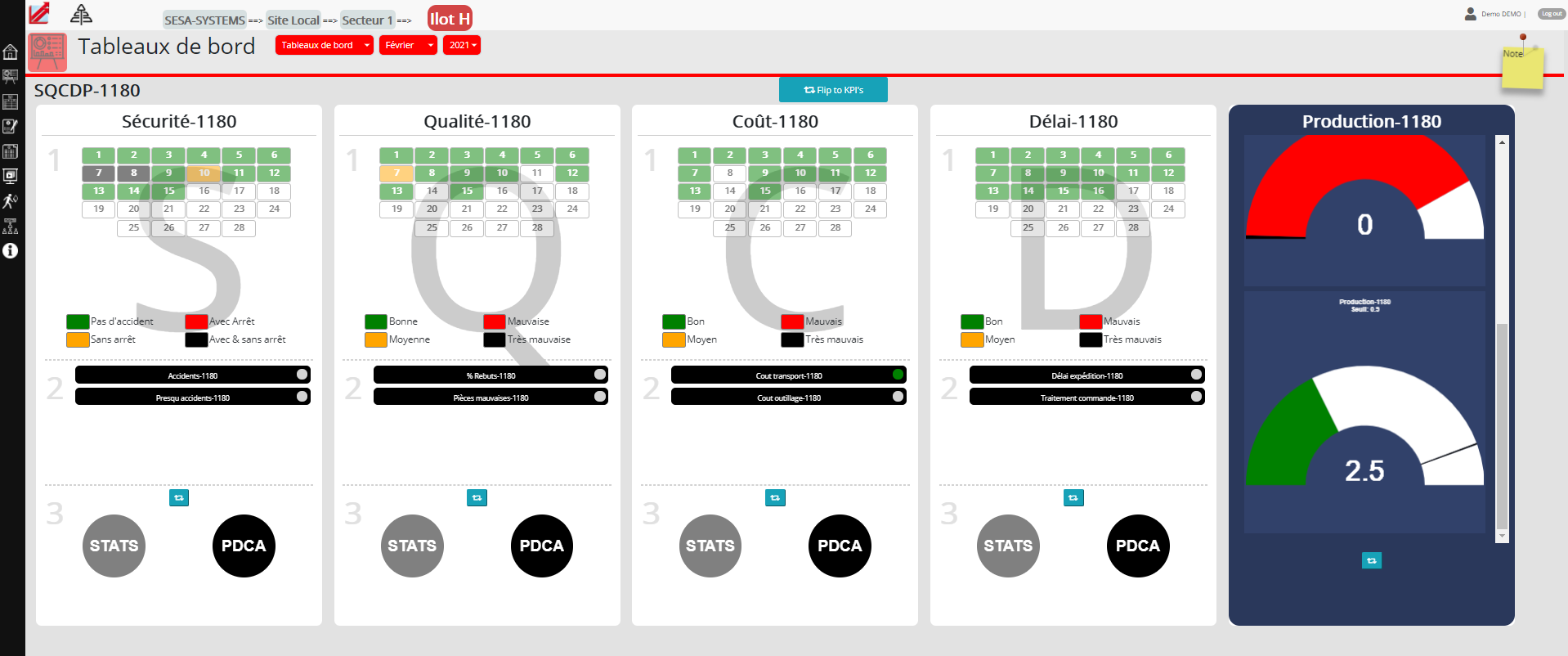

The SQCDP method is one of the most popular visual management methods. It was mainly applied by companies in the aeronautics industry and tends to spread in the industrial environment. SQCDP is an abbreviation for "Safety, Quality, Cost, Time, People". Its extremely simple operation highlights an overview of how it works on a monthly basis. It is a very useful collaborative tool, which can often be integrated into an operational dashboard, for monitoring objectives. By orienting yourself towards this method, your company will position itself in a Kaizen process of continuous improvement. This is why the SQCDP method will help you overcome all the difficulties of everyday life in order to guarantee the sustainability of your company's production.

The purpose of this method is to achieve flawless production and operating processes.

Concretely, the SQCDP tool is available in the form of tables, each table includes a box corresponding to each day of the month (the SQCDP takes place over 1 month). At the end of each day, the team meets and decides to color the box of the day in question:

Green if everything went well.

Red if a problem has occurred (defects, breakdowns, accident...).

If a problem has arisen, then the company must take the necessary measures. This process is repeated every day and allows at the end of the month, to have a very visual report of the performance and the good functioning of the team over this period.

The operation of this method is very simple but contrary to popular belief, the decisions made when filling in the boxes at the end of each day are not arbitrary. In fact, each of the 5 letters has a number of criteria to consider. However, there is no defined list for every aspect of the method. The choice of criteria depends on the relevance of internal indicators and methods. The SQCDP method is a very visual method that must be very synthetic, so not all indicators will be included in this method. These KPIs (Key Performance Indicator) must be well chosen because they will give a very clear general signal at the end of the day (red or green).

It is possible to divide the application of the SQCDP method into 4 steps:

Their choice will condition the overall perception that a company will have on the dimensions it wishes to evaluate. If indicators are not in perfect agreement with the objectives of the evaluation, then the application of the SQCDP method will be in vain. To give you some examples of criteria that you can remember, here is an example of a non-exhaustive list:

For this, the painting must be both large and modular to be able to integrate into your environment. E-Meetings allow you, for example, to benefit from a large interactive digital screen, convenient for collaborative work. You can connect your screen to a computer or to the SESAHUB software, which will give you real-time indicator monitoring. This tool offers great ergonomics and facilitates teamwork.

Making the dashboard visible/accessible to the entire team is the essential step which consists in taking into account the previously defined indicators to assign to the box of each letter one of the 2 colors. If problems have arisen, then this is an opportunity for the team to remedy them by planning action plans for the coming days. The SQCDP method corresponds in many respects to the Plan Do Check Act (PDCA) method, in a more simplified but more visual way.

Thanks to the nature of an SQCDP table, global trends can be instantly identified. Thus, in addition to daily action plans, it is possible for teams to work for greater changes in their operations and processes. If, on the other hand, the results are positive, then it is appropriate for the teams to set themselves again. Otherwise, the daily monitoring of a team's performance is of little interest if it is not challenging. It is necessary to be part of a process of continuous improvement! Of course, good performance must be recognized and valued by the company to maintain the commitment of employees that contributes to the improvement of their productivity.

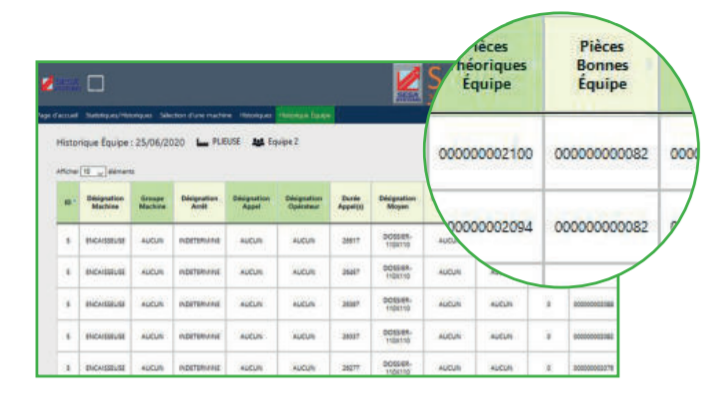

This is a method that has greatly inspired our vision and use of Digital Visual Management. To be able to guarantee a quality service and supervise the production and operation of our workshops, we have created the SESA MES, MES system for Manufacturing Executive Action. Directly connected to our production machines, this tool allows you to generate accurate and updated indicators in real time on the status of your production. The MES tablet is designed to be used for workshop activities. Its format allows this tablet to be particularly mobile thanks to a shoulder holder and a resistant case.

Once these indicators are collected, it is possible to select a few to set up your dashboard. To do this, you can use our sesahub collaborative platform, which allows you to centralize data and format your dashboards.

The points mentioned will allow you to better supervise your different teams and to have relevant elements to integrate into your decision-making. The implementation of action plans following the monitoring of your KPIs (Key Performance Indicator) will lead you to a significant performance gain.

Find now our other Digital Visual Management solutions, to increase your daily performance and facilitate the monitoring of your indicators and integrate your company in a logic of continuous improvement.

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.