300 novelties

to fully satisfy you

LEAN tools and approaches

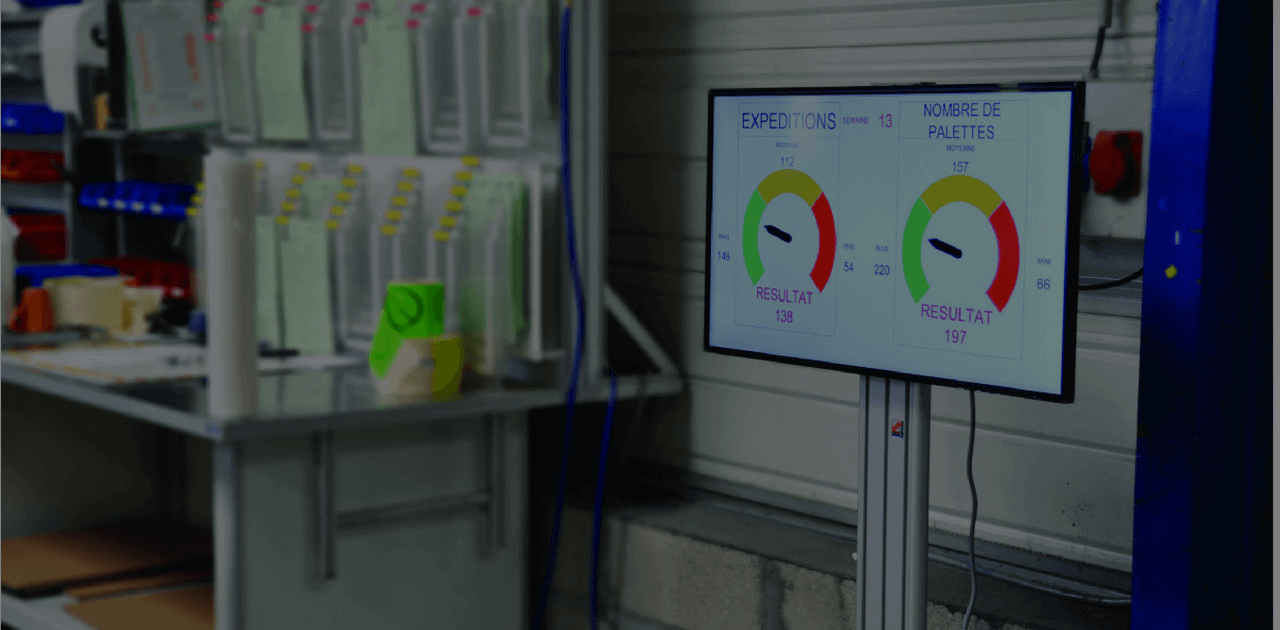

An indicator is objective data that describes a situation from the strict quantitative point of view that shows a result. But the indicator will only have real meaning in the predefined framework if it "indicates" where action is needed. If you take, for example, a dashboard of a car, the oil level indicator is a visual management tool directly connected to the oil pan. Thus a drop in the oil level will be immediately signaled and the indicator light will come on. This is an example of a good indicator since it is directly related to the action area! It provides the user with up-to-date, targeted information that allows them to take action when needed.

Performance indicators are at the heart of Visual Management, a form of management that uses visual and verbal communication to facilitate daily improvement and constantly offer the various messages and indicators needed to accomplish the various missions entrusted to the teams. For example the TRS Synthetic Rate of Return, is a machine performance indicator.

Which measurements you take note of are important. Concerning the use of machines, it is the net production of conforming quality that determines the actual useful output in relation to the theoretical quantity that could have been produced during the opening hours. The use of labor is the total paid time compared to the time allocated which finally expresses real productivity. Frequently, only the time spent at work stations is retained and unproductive time, sometimes far from negligible, is charged to other accounts. However, the remuneration inherent to these unproductive, under-productivity times is well reflected in cost prices.

The consumption of materials and components is the mass of purchases that must be compared to their useful value in the products actually sold. For delays, it is interesting to note from time to time the overall "flow time" of the plant, from the date the main component is picked up to the date the finished product is deposited at the shipping dock. This reference represents the production's real-time. The production unit time is then compared to this reference.

The outcome of measuring these actual performances leads to an exhaustive identification of the extent of the losses between the available resources and their use. These losses constitute the potential for progress, and it is on this impartial basis that animation must be developed through the use of objectives.

These objectives give the measure its full meaning. On the basis of the classification of losses, and for each one, it is necessary to decide on the possibilities of progress achievable in the short to medium term. We therefore objectively quantify the level of results that we wish to achieve thanks to dedicated resources. This means investments in equipment, staff training, the introduction of methodological approaches, organizational changes, and the strengthening of facilitation methods.

It is likely that not all losses can be taken into account simultaneously and it is necessary to draw up a chronology according to 2 possibilities:

- The application of the Pareto analysis, in decreasing order of importance of the results. Pareto allows you to classify the causes of problems in order of importance and thus to visualize the most embarrassing causes. (20% of causes producing 80% of effects).

- The resolution of small losses that require little effort and delay, allowing you to reap immediate benefit.

The presentation of the four axes of progress, Machine, Material, Labor, Flow explains the main approach to improving industrial performance through the application of methodological tools such as HOSHIN, SMED or TPM. The widely confirmed practice shows that the whole satisfies almost all the know-how needs for continuous improvement in production. But in some cases, it doesn't work. We will therefore study why, i.e. the different causes of non-performance.

The three broad categories listed below classify causes of underutilization and yield losses:

We will seek to optimize the output of production equipment in order to maximize the return on investment and limit the costs associated with its operation to the strict minimum. In concrete terms, beyond the concern to safeguard the equipment's initial new condition throughout its life with the goal of the slightest risk of breakdown, all other sources of stoppages and underperformance, whether organized or random, will be screened in order to minimise their impact on operating time.

In addition to the losses due to non-quality at successive stages of production, all unnecessary consumption linked to the technical nature of the manufacturing process and organizational malfunctions are taken into account from the moment the product enters the factory until it is shipped:

Time losses are grouped into four categories as mentioned below:

These will help to organize time savings and optimize time use. While knowing that the objective will be the rationalization of manufacturing methods and means, but more widely the most efficient use of all paid hours, whether direct or indirect labor.

Just-in-time is the slogan of the factory without stock but able to guarantee the promised delivery time. The losses of time or delay encountered are represented in the form of three categories:

Based on the adapted conditions of the production tool's flexibility, the approach will aim to shorten as much as possible the crossing time of the plant (flow time), from the handling of materials and components to the provision of finished products.

Discover SESA SYSTEMS creations to display performance indicators in real time.

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.