Manufacturer of industrial furniture specialized in Lean Manufacturing

Expert in LEAN Manufacturing and visual management

Ergonomie

It is time to develop the Quality of Life at Work and to integrate ergonomics into the heart of your premises. Improving working conditions, reducing waste and enhancing and satisfying your employees. Discover our comprehensive workplace safety solutions that adapt to the various tasks of your employees while taking ergonomic aspects into account.

Discover the range

Ergonomie

It is time to develop the Quality of Life at Work and to integrate ergonomics into the heart of your premises. Improving working conditions, reducing waste and enhancing and satisfying your employees. Discover our comprehensive workplace safety solutions that adapt to the various tasks of your employees while taking ergonomic aspects into account.

Discover the range

Marking and security

Being able to identify risks, avoid potential dangers and point out safety instructions is essential. Industrial security helps you mark out, organize and identify your premises. It is a stakeholder in continuous improvement which guarantees the safety of all, anticipates risks to improve the safety and working conditions of all your employees.

Discover the range

Marking and security

Being able to identify risks, avoid potential dangers and point out safety instructions is essential. Industrial security helps you mark out, organize and identify your premises. It is a stakeholder in continuous improvement which guarantees the safety of all, anticipates risks to improve the safety and working conditions of all your employees.

Discover the range

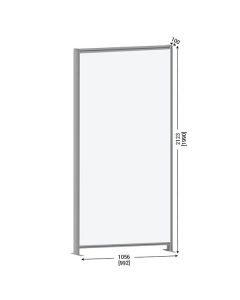

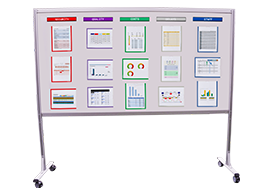

Visual Management

Visual Management is management and organization by sight. It is mainly based on techniques for transmitting information and monitoring the achievement of objectives. Consult our full range of display boards and visual aids to present your performance indicators and procedures in your workspace.

Discover the range

Visual Management

Visual Management is management and organization by sight. It is mainly based on techniques for transmitting information and monitoring the achievement of objectives. Consult our full range of display boards and visual aids to present your performance indicators and procedures in your workspace.

Discover the range

300 novelties

to fully satisfy you

LEAN tools and approaches

Visual Management, adopt good reflexes thanks to an effective display in your company.

Visual Management relies on communication and visual display techniques to share information and monitor the achievement of objectives. It is an organizational technique that essentially passes through the eye and is based on color codes, graphics or various indicators to assess the team’s performance against the objectives that have been set. SESA SYSTEMS offers different products to set up these principles in your company thus that your employees are more efficient and know how to situate themselves according to the objectives set.

Industry 4.0, a revolution made possible thanks to connected technologies.

Industry 4.0 includes an innovative product line to integrate the factory of the future. Indeed, thanks to the constant connectivity of our objects and screens increasingly ubiquitous in our lives, we are able to share information in real time throughout the company. It then becomes easy to share follow-up indicators or performance to all company departments in a digital visual management approach. In addition, these computer tools are also used to present meetings or interactive animations in order to take advantage of this type of display.

SESA SYSTEMS, ergonomic office furniture manufacturer, offers a complete range of office furniture

Find a complete range of ergonomic office furniture at SESA SYSTEMS. Design and original, the products offered give you the opportunity to create a pleasant and neat work environment. Focused on ergonomics and LEAN Office, they also offer a comfortable and suitable framework for employees. Both aesthetic and functional, our products manufactured in France ensure the comfort of employees by offering practical solutions for office work. Since this furniture comes in several sizes, just choose the model that suits you. You can complete it with an ergonomic office chair, or various accessories to customize it to your needs. A pleasant and well-organized framework to best apply the LEAN Office principles.

Optimal management of your processes and resources thanks to LEAN Manufacturing solutions from SESA SYSTEMS

To identify and eliminate waste, LEAN Manufacturing is an approach that improves production. Thanks to the solutions offered by SESA SYSTEMS, you will be able to manage your processes and resources optimally. Unnecessary tasks that do not contribute to value creation will no longer have their place in your business. In addition, your stocks will be reduced and your feeds improved. To revolutionize the organization of your workstations, SESA SYSTEMS offers different positions studied for all situations including an ergonomic range and an INOX range for environments where it is necessary. Modern and innovative, these clever products adapt to all sectors of activity thanks to a large capacity of customization.

Innovative logistics solutions to reduce stock and logistics costs.

SESA SYSTEMS also offers customized solutions for dynamic storage. Thanks to the LEANDYNAMIC that you fully customize according to your needs, you are able to reduce the length of lines, optimize your stocks and eliminate unnecessary conveyors. The operators then focus only on the tasks and gestures providing real added value while getting rid of the rest. They are then more productive and their work is better studied. We also offer several KANBAN planning tools as well as several models of mobile services and trolleys for end-to-end control of your logistics service.

The road marking, essential for a safe and well organized workshop.

Workplace accidents are never a good thing and all companies put in place several actions to avoid them. SESA SYSTEMS offers you a range of tools to apply these actions. In fact, the products in this range will enable you to identify risk areas in your company and to clearly indicate them to employees and potential visitors. Safety instructions can then be displayed and various pictograms will be used to identify risks or to protect operators. Thanks to these products, you will be able to organize your offices and workshops correctly to avoid accidents at work!

Playful training games to discover and apply LEAN in a company

SESA SYSTEMS also develops all kinds of support tools for LEAN Management, like the educational training games that allow you to discover and apply the different LEAN methods. These simple games, to be played as a team to discover several issues and how LEAN methods can provide a solution. Once the training is over, the company has the opportunity to start a pilot project on its premises thanks to the start-up kits provided for this purpose. The goal is to give a certain autonomy to the collaborators thus that they can apply in a concrete way the theory seen during the game.