300 novelties

to fully satisfy you

LEAN tools and approaches

Heijunka is a Japanese term meaning levelling, which results in a smoother production flow. Production leveling is a production planning method that impacts the efficiency of your operations. It is a Lean Manufacturing tool and is used to implement the JIT method, just-in-time. Thus it participates in the TPS (Toyota Production System).

The principle of smoothing is based on planning time of production according to an average quantity to be produced. This quantity is calculated in advance to establish a repetitive process that produces the same quantity of product each day. Thus creating an average rhythm of production in order to reduce possible variations in the management of customer orders, production volume, finished product storage and costs.

However, it is not possible for all manufacturers to produce the same quantity of products every day because they have several ranges and/or types of products. This implies a different production or assembly time. This is why this smoothing technique exists for each type of product. As a result, delivery times and costs will be reduced while increasing quality. Quality, cost and lead time factors are therefore improved, which represents the fundamentals of Lean Manufacturing.

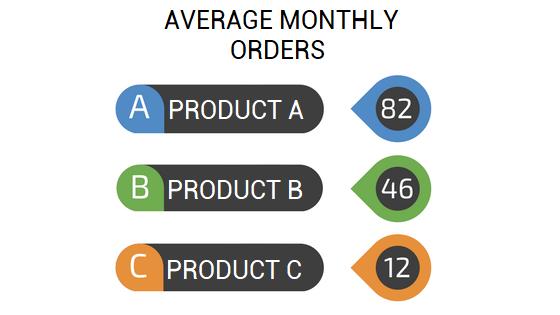

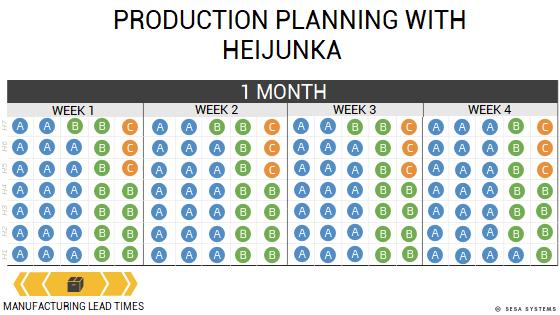

Take a factory that manufactures 3 types of products in different volumes and/or quantities. Here is the representation of the 3 products with a different color for each. Now imagine the average monthly number of orders for each product line.

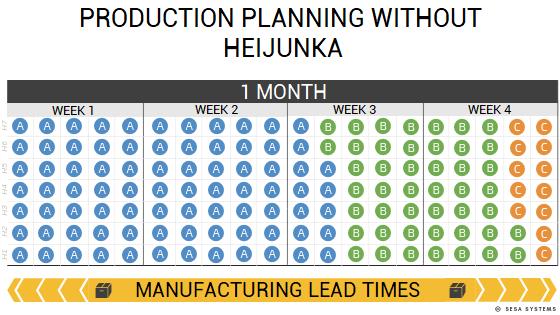

Without Heijunka, the company will first mass produce and chain the most consumed products and end by producing the least consumed products. This avoids the need to change series and molds between each product to minimize time wasted. Below is what production looks like when Heijunka is implemented.

Now, let us imagine that the company receives an order from a customer at the beginning of the month for 3 products. We'll have to wait until the end of the month to deliver that product to the client. This represents logistics and management costs of at least 20 working days. This duration is not acceptable for the company or for the customer.

The company may initially produce the following C products in small quantities. But the delivery time will always remain the same from the time the sales order is placed in the middle of the month to when the C products have been consumed. There can be an improvement of a few days for delivery but it is still not optimal.

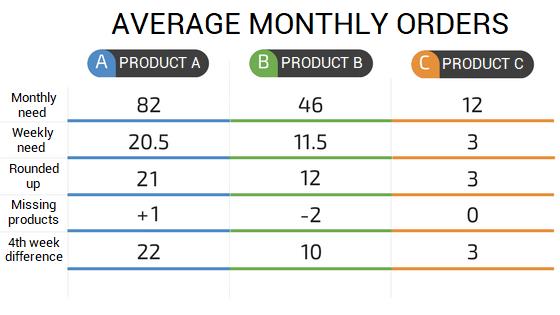

The Heijunka method therefore offers the best improvement in terms of flows. To begin with, the production must be distributed in a repetitive, rhythmic manner. Let's take the week as a mesh. The mesh represents the base, the base, the plane that we will repeat.

According to Heijunka, the company with its 3 product categories will have the following manufacturing schedule. The Kanban method can facilitate the production volume in order to respect the created rhythm.

With this method, delivery times are reduced to a minimum of 3 days for the sales order to be delivered. The performance of Heijunka can be verified by Takt Time.

This example shows that Heijunka is a Lean Manufacturing method for levelling production. This levelling is done on the manufacturing process in order to reduce production times and in return, delivery times. In today's harsh market, it is important for your company to distinguish itself from your competitors. Your delivery time is a decisive factor in the eyes of the customers. It is therefore necessary to reduce lead times as much as possible in order to satisfy customers and gain market share.

In addition to the benefits already detailed, Heijunka's performance can be checked by Takt Time, allowing you to constantly improve your production performance while reducing unnecessary waiting time. There are also other LEAN methods to improve your production, such as JIT, just-in-time stock and in-process management.

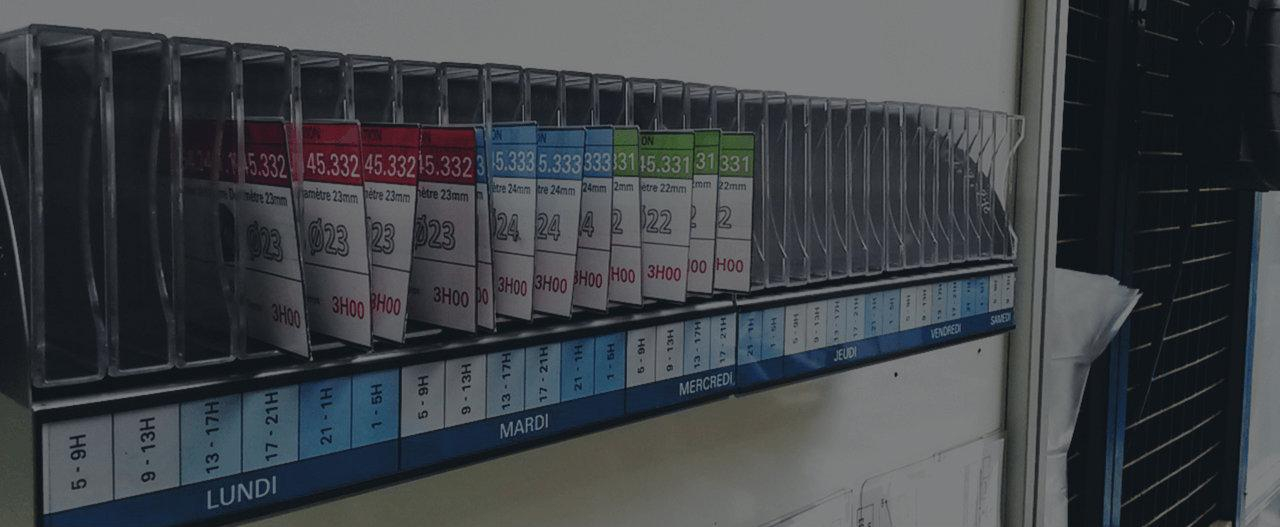

Discover SESA SYSTEMS creations for the improvement of production logistics.

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.