300 novelties

to fully satisfy you

LEAN tools and approaches

Continuous improvement of the supplier-customer relationship is essential for maintaining strong, long-term partnerships. Optimizing inventory management to maintain only what is strictly necessary is a key solution for ensuring flexibility and delivering maximum service. In this context, the Kanban method is a tool that supports just-in-time (JIT) production, theoretically enabling operations with zero or minimal inventory. Kanban is therefore designed to drive industrial improvements by optimizing logistics and reducing material storage costs in warehouses.

Kanban is a card or tag that accompanies each batch of parts. This simple "piece" of paper becomes a crucial visual signal in a Kanban system, indicating when and how much to produce. The goal is to pull production based on actual consumption. When it enters the loop, the Kanban card triggers either replenishment or the production of a batch.

A Kanban card contains three types of information:

Part number and quantity per container, optionally including a photo of the part.

Identification of the customer and supplier, the location for depositing containers, and the spot for placing released Kanban cards.

Number of Kanban tags in circulation for the part reference and the batch size for launching production. This allows for easy verification that the implemented Kanban loop contributes to reducing the company's inventory levels.

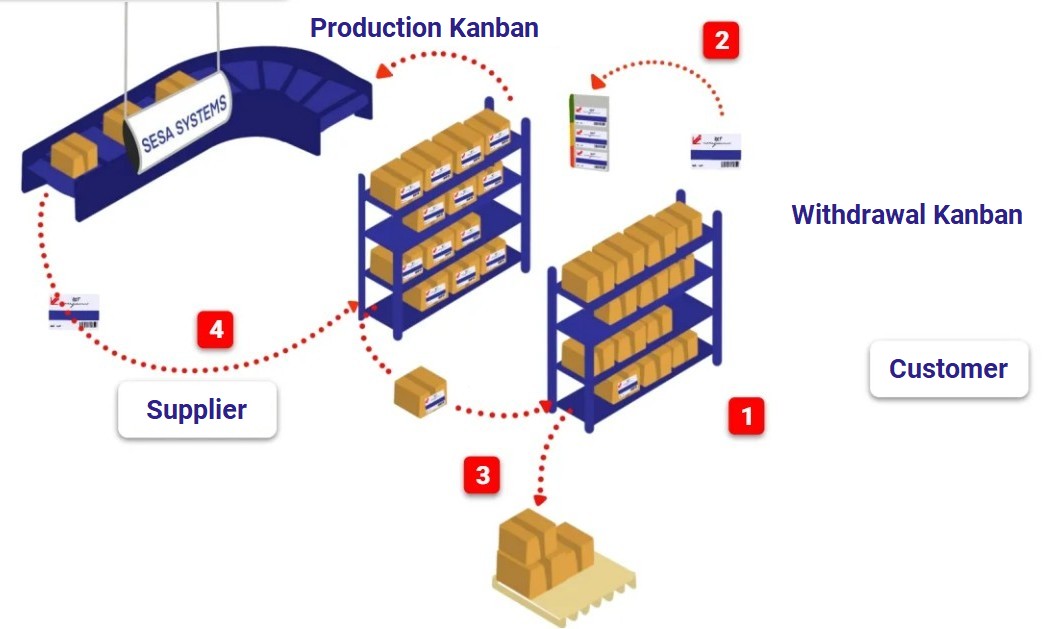

A Kanban loop is the circuit followed by Kanban cards. For a given part number, it includes the exact number of Kanban cards needed to ensure continuous supply (or replenishment) from supplier to customer. Too few Kanban cards will result in insufficient production to meet customer demand. Conversely, too many cards in circulation will lead to overproduction and excessive stock buildup.

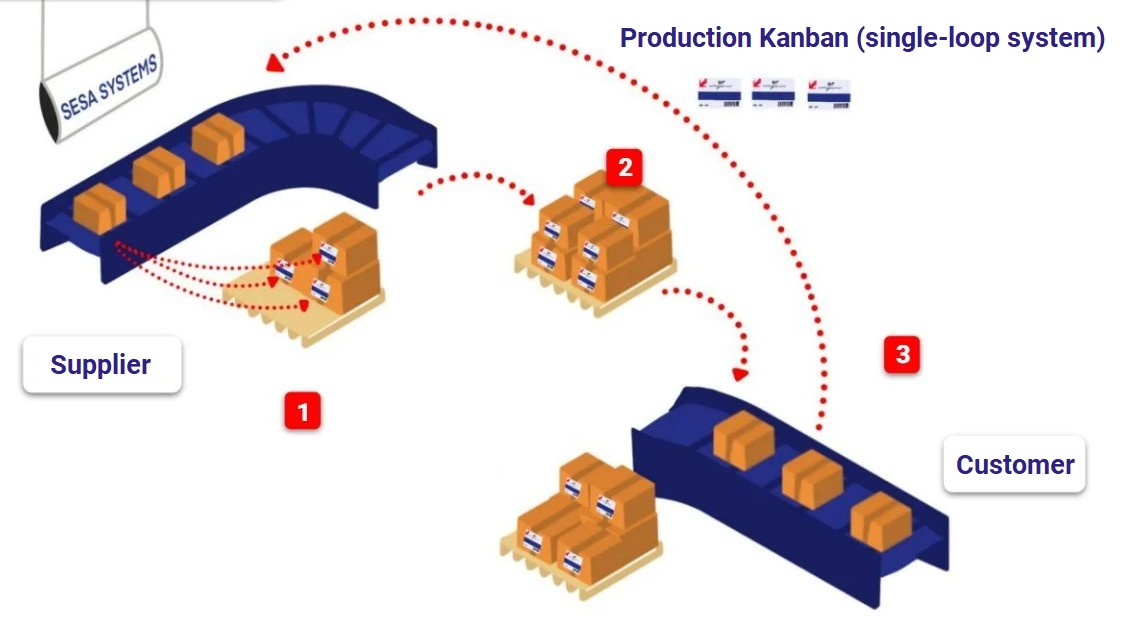

Kanban organizes production using a pull flow: the customer is downstream and drives the supplier’s upstream production.

This means that customer orders automatically trigger manufacturing tasks, with production orders flowing backward from product delivery.

There are two types of Kanban, Production Kanban (single-loop) and Withdrawal or Transfer Kanban (dual-loop)

The Kanban method first emerged in Toyota factories. Many well-known methodologies—such as the 5S method and TPM (Total Productive Maintenance)—also originate from the Toyota Production System (TPS). The pioneer behind this production management method was Taiichi Ōno, a Japanese engineer.

Beyond the manufacturing sector, the Kanban method is also widely used as a project management system, similar to Agile and Scrum frameworks.

This production system can be applied to any point in the workflow, including:

The Kanban system enables manufacturing control through a visual scheduling method that triggers production orders based on real consumption. It fosters a simple and continuous supplier-customer relationship. Inventory levels are tightly controlled, maintained within a range that ensures on-time deliveries while preventing shortages or overstock.

The Kanban method is particularly well-suited for large and medium production runs where flow has been standardized. With a few adjustments, it can also be applied to small batch production.

Kanban can become a key improvement tool, forming the foundation upon which other performance-enhancing actions are built, such as:

The two-bin system is a simple yet highly effective application of the Kanban method, particularly at workstations or in storage areas. It is based on using two bins, each containing an identical quantity of the same component. When one bin is emptied, it is moved to a replenishment point, and consumption continues with the second bin. The empty bin, paired with a Kanban card, then triggers a restocking order. This mechanism ensures a continuous flow while fully adhering to Just-in-Time (JIT) principles.

One of the key advantages of the Kanban system is its ability to make disruptions in the production flow visible. For instance, if a Kanban card is missing, if an upstream workstation isn’t being replenished, or if bins begin to accumulate without being removed, it instantly signals a break or blockage in the process.

This visual transparency allows both operators and managers to respond quickly—without waiting for a report or digital alert. The system highlights problems in real time, encouraging proactive and continuous improvement.

In an industrial setting, each Kanban card is typically linked to a physical unit of production or storage—often a standardized box, bin, or container. Standardization enables precise control over the quantities produced or moved, ensures smooth replenishment, and simplifies the calculation of required stock at each step of the process.

The container thus becomes a visual indicator of production flow and a trigger for logistical actions.

It is often believed that keeping inventory helps ensure deliveries despite machine breakdowns, quality defects, or imbalances in production lines.

However, this convenience comes at a high cost. While inventory can soften the immediate impact of production issues, it does not reduce the cost of these anomalies. Worse, the false sense of security created by stock leads to a lack of discipline in resource management, which inevitably causes production costs to spiral. Inventory hides real production problems—and more importantly, it becomes a powerful barrier to progress.

Constantly seeking to lower inventory levels is part of a continuous improvement approach aimed solely at eliminating the uncertainties that disrupt manufacturing and increase costs. For a supplier, the fundamental rule is to produce only the exact quantity of conforming parts that the customer needs, when they need them, while maintaining a reasonable stock level. Applying the Kanban system supports this goal.

Kanban, a Japanese term meaning “label” or “tag,” is a method of managing material flow based on the exchange of visual information between a customer and a supplier. It enables:

The Kanban Method Helps Reduce:

The effectiveness of the Kanban system can only be ensured if a few simple rules are strictly followed by everyone involved in the movement of Kanban cards.

First, each full container is tagged with a Kanban card, and the customer releases the Kanban card once they consume the contents of that container. The containers must always contain the exact number of pieces indicated on the label.

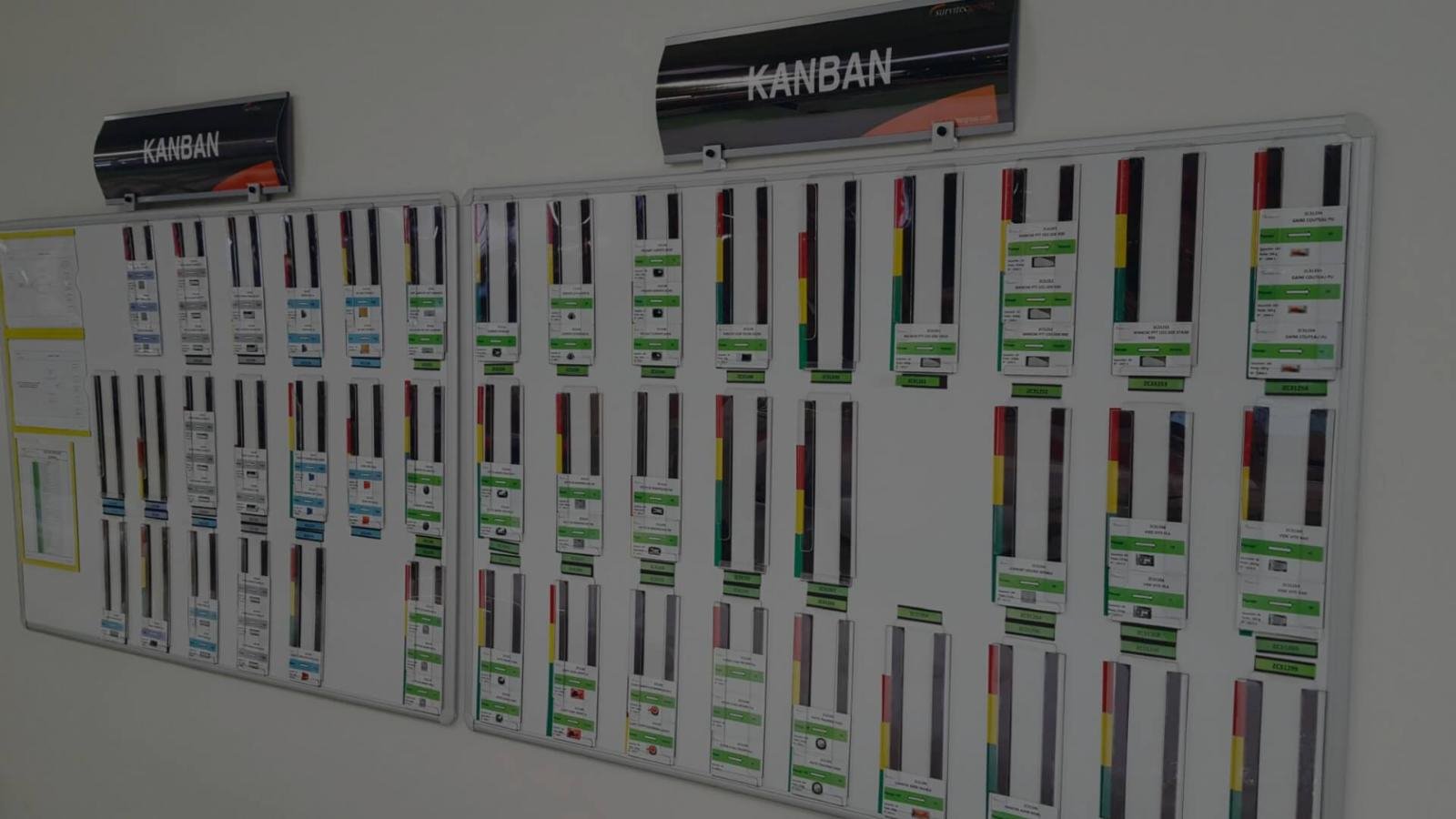

Next, the customer must return the Kanban cards to the supplier once they have been released. The free Kanban cards should be displayed on the Kanban board.

To maintain a consistent product consumption rate at the customer’s end, it is common to color-code the Kanban areas to make them more visually intuitive. Manufacturing orders are initiated by monitoring the Kanban board. The thresholds are used to prioritize production, with the board providing real-time insights into the customer’s consumption. This enables timely and accurate resource allocation.

There are also methods for calculating these thresholds.

Green Zone (Optimal threshold): This corresponds to the minimal batch size for production. When Kanban cards are in this zone, production is not authorized.

Orange or Yellow Zone (Critical threshold): This zone is located between the green and red zones. It serves as a buffer zone to absorb fluctuations in downstream demand and supplier uncertainties. It also allows prioritization between different product references. When the cards are in this zone, production can be triggered.

Red Zone (Alert threshold): When the queue reaches this zone, production must be launched urgently, as there is a risk of a supply shortage for the customer. In the red zone, the supplier must contact the customer to report any issues. This safety zone helps absorb unforeseen circumstances and significant demand fluctuations.

In some cases, it is imperative to follow the FIFO (First In, First Out) rule, particularly for product freshness, material expiration, and quality maintenance. In all other cases, FIFO is strongly recommended.

Don’t wait to train your teams in the Kanban method through play-based learning.

The Kanban Starter Kit is the perfect complement to classroom-based Kanban training. It includes all the necessary tools for immediate, hands-on application during a Kanban workshop on the field.

The result? A clear and effective demonstration of just how simple a Kanban project can be.

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.