Blog LEAN

Kako preprečiti zamude v proizvodnji? 5 ključev za optimizacijo načrtovanja

Zamude v proizvodnji so lahko velik izziv za vsako industrijsko podjetje. Pomenijo dodatne stroške, nezadovoljstvo strank in lahko vplivajo na konkurenčnost na trgu. Vendar pa lahko natančno in optimizirano načrtovanje...

Zakaj uvesti digitalni vizualni management za industrijsko proizvodno ekipo?

Digitalni vizualni management je sodoben pristop, ki izboljšuje upravljanje industrijskih proizvodnih ekip z izboljšanjem komunikacije, produktivnosti in kakovosti. Uvedba te metodologije prinaša številne specifične koristi za industrijski sektor, zaradi česar...

Zakaj uporabljati metodo 5S?

Metoda 5S, ki izvira iz Japonske, je sistematičen pristop, katerega cilj je učinkovito in varno organizirati delovne prostore. Ta metoda vitkega upravljanja (LEAN Management) je razdeljena na pet korakov —...

Kako usposobiti in ozavestiti svoje ekipe o metodi 5S?

Metoda 5S, ki izvira iz Lean Manufacturinga, je ključna za vzpostavitev učinkovitega, varnega in dobro organiziranega delovnega okolja. Uporablja se lahko tako v pisarniškem kot tudi v proizvodnem okolju in...

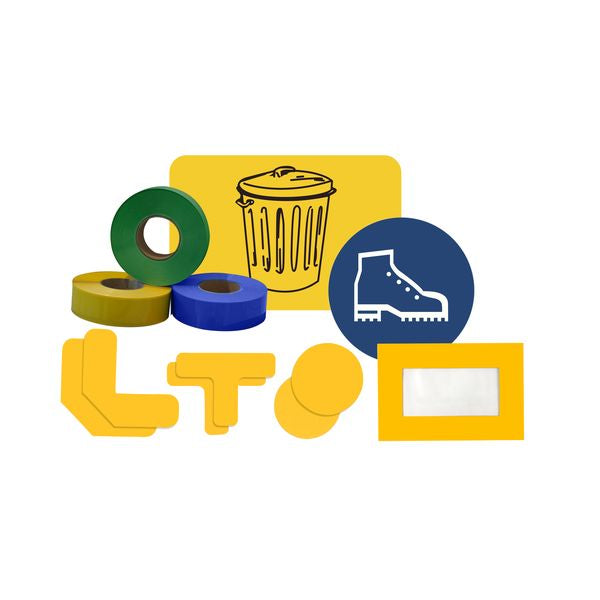

Kako narediti talni označevalni sistem v industrijskem okolju?

Talni označevalni sistem je ključni element v industrijskih proizvodnih okoljih. Povezan je z vizualnim upravljanjem in širšo filozofijo LEAN proizvodnje, saj omogoča organizacijo skladišč, prostorov, izboljšanje produktivnosti in predvsem povečuje...

Kako uporabljati metodo KANBAN?

Metoda Kanban, ki izvira iz proizvodnega sistema Toyote v 40. letih 20. stoletja, je pristop za upravljanje delovnih tokov, ki si prizadeva za optimizacijo učinkovitosti in produktivnosti ekip. Temelji na...

How to Improve Work Processes with LEAN Methods?

What is LEAN? In a world where competition is increasingly fierce and companies are constantly seeking to maximize their efficiency to better meet customer needs, LEAN emerges as a powerful...

How to Optimize Order Preparation and Packaging with the PACKINGPOST Range?

Optimizing order preparation and packaging in warehouses is a crucial goal for companies aiming to enhance logistical efficiency and reduce operational costs. Achieving this requires a methodical approach, proper workspace...

How to Equip Your Workspace Ergonomically?

A well-organized workspace is essential for boosting productivity, enhancing comfort, and reducing the risk of discomfort from poor posture. Ergonomics, when applied to a workspace, plays a crucial role in...

What Size for a Digital Meeting Room?

The ideal size of a meeting room is a key consideration when designing a functional and productive workspace. It must account for several criteria, such as the number of participants,...

Why Use Safety Barriers in Production Workshops?

Using safety barriers in production workshops is crucial for ensuring worker protection and smooth operational flow. For companies committed to employee safety, these devices play a vital role by preventing...

What is LEAN Logistics?

Lean Logistics is a supply chain and logistics operations management method aimed at maximizing efficiency by reducing waste. Inspired by the principles of Lean Management, initially developed in the manufacturing...