Blog LEAN

How to Optimize Production Lines Through LEAN Manufacturing?

LEAN Manufacturing (not to be confused with LEAN Management) is a production management approach focused on maximizing customer value while minimizing waste and costs. Drawing from the Toyota Production System's...

How to Complete a PDCA Cycle?

The PDCA cycle (Plan-Do-Check-Act), also known as the Deming Wheel, is an iterative Lean method for quality management and continuous improvement. This means that each completed step leads to the...

How to Organize a Continuous Improvement Process in a Company with LEAN?

Continuous improvement is a fundamental pillar of effective business management. LEAN Management (and LEAN Manufacturing), inspired by Toyota’s production principles, provides a structured approach using various methods to optimize processes,...

What is the Purpose of LEAN?

The LEAN concept, initiated by Toyota in the 1950s, has become a cornerstone for efficient operations and resource management across various industrial and organizational fields. Whether in manufacturing (LEAN Manufacturing),...

How to Implement the Kanban Method in 5 Steps?

The Kanban method, initially developed by Toyota as part of its production system, has expanded beyond the automotive industry to become a widely-used approach in various sectors, including office environments,...

How to Raise Team Awareness about the 5S Method?

Implementing the principles of the 5S method is crucial for ensuring an efficient, organized, and safe working environment. Originating from the Japanese LEAN Management approach to quality management, the 5S...

How to move from physical visual management to digital?

With the development of online services, production companies are increasingly moving towards the factory of the future. That is, the processes are digitized and move from a physical medium to...

Discover Industry 4.0 and its applications in production

Visual Management and Industry 4.0 Visual management makes it possible to know about an area of activity whether the situation is normal or abnormal. The goal is to quickly visualize...

6 Criteria to Create an Innovative, Efficient, and Creative Workspace!

Work environment can be a determining factor in the productivity of employees as well as their daily motivation. Workspaces are where we spend most of our time and days. It...

5 tips for Successful Digital Transformation!

In the digital age, companies must adapt to the challenges of digital transformation regardless of industry. New technologies are organizational assets, they improve service, tools, and overall productivity. This change...

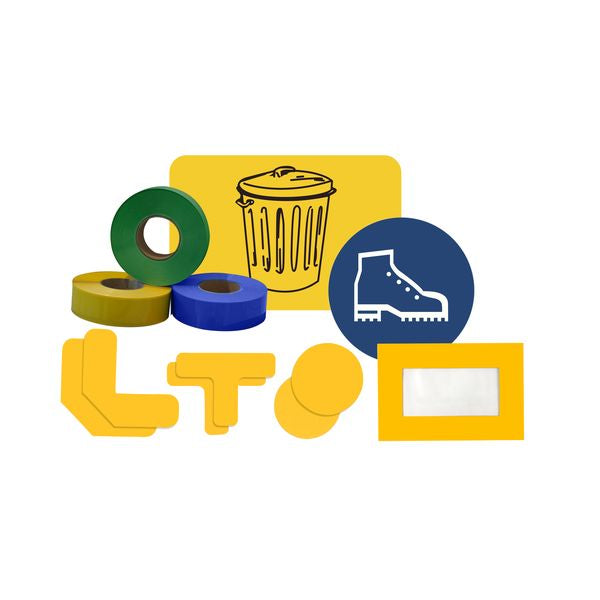

The document holder, an ideal solution for quick access to your important documents

Briefcases are practical and efficient products for displaying various documents. Discover the whole range Why Use Document Holders? Using a document holder has several advantages, on the one hand documents remain...

5S omare za shranjevanje za boljšo organizacijo vašega delovnega okolja

Urejeno shranjevanje je bistvenega pomena za ohranjanje čistega in urejenega delovnega okolja. Pravzaprav je dobra organizacija pogosto povezana z učinkovitostjo. Zato podjetja uporabljajo omare za shranjevanje. Vendar večina teh omar...