ESD equipment: Avoid costs for quality defects by protecting your sensitive components

DOWNLOAD THE STAINLESS STEEL/ESD GUIDE

What is ESD ?

ESD stands for "ElectroStatic Discharge".

Static discharges are physical processes that occur every day when two bodies are charged differently. One discharges onto the other.

We have all felt this more or less unpleasant sensation one day when removing a plastic film on a support, when brushing our hair, on the door when getting out of our car, during a storm.

We feel them from about 3000 Volts, we hear them from 5000 Volts, we see them from 10000 Volts.

Why are we interested in ESD?

Although most of the time these discharges go unnoticed and are harmless to humans (90% of electrostatic discharges are below 3000 V), the effect they can have on equipment, electrical or electronic components such as semiconductors is disastrous. More than 60% of component and peripherial faults are due to uncontrolled electrostatic discharges

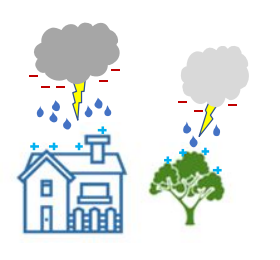

For example, an electrostatic discharge on an electronic component of the order of 25 Volts can be similar to that of lightning striking a tree on a microscopic scale. As components become more and more miniaturized, their fragility increases.

The damage caused by discharges can cause irreparable breakdowns (the component is destroyed and no longer fulfils its functions) or hidden defects (the component is weakened, its behaviour is unstable and can lead to breakdowns in the more or less long term).

The presence of this ESD effect is therefore very difficult to detect because the damageis not always immediately visible.

The cost of failures, caused by electrostatic discharges on these electronic components is estimated at several million euros in France per year. These costs include claims, diagnostics, repair costs, loss of corporate image.

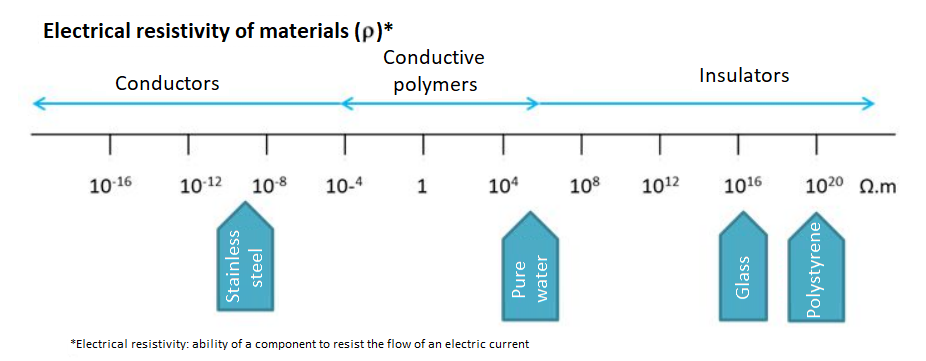

How do the different materials behave?

There are three main families of materials:

- Conductive materials: of low electrical resistance, they do not capitalize on charges. The current passes through whatever the situation, to a certain extent (metals, graphite, salt water).

- Insulators: The properties of the material prevent the dispersion of charges, which means that no electric current can be transmitted through the material (glass, wood, plastics, ceramics, paper, air).

- Dissipative materials: they dissipate electrostatic charges in a controlled and durable manner, further removing the risk of potential damage. (Conductive polymers for boxes, foam, tubs, bags, film...).

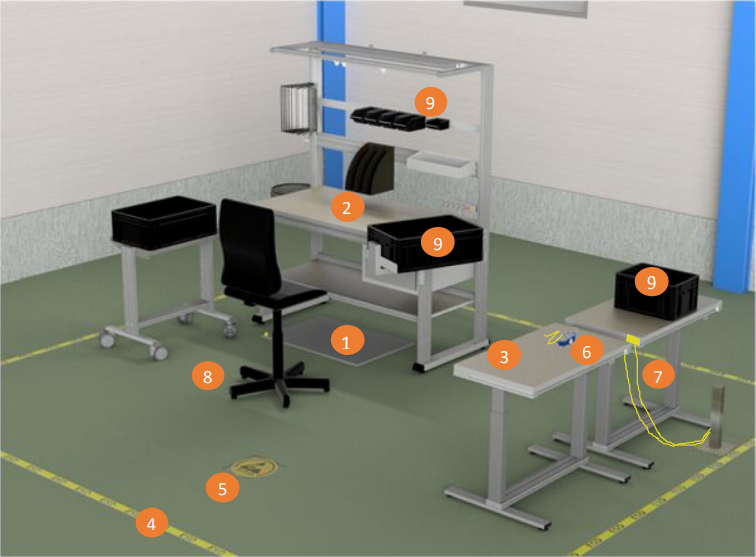

The work area (EPA)

The EPA (Electrostatic Protected Area): this is an area delimited and protected from electrostatic discharges. This area can be a work surface, an island, a room, or even a building. Only authorised persons are allowed in this area and they must be equipped with earthing devices (bracelets, shoes or heels, appropriate work clothing).

EPA is not incompatible with workplace ergonomics.

It must be sufficiently dimensioned to allow operators to work comfortably while respecting postures.

The ideal solution is to provide:

- On the floor an ESD cover or mat on which the operator can be unloaded

- A workstation by its nature or equipped with one or more ESD coatings as required

- A bracelet device that the operator wears tightly on the wrist

- Grounding

The EPA shall provide signage to clearly identify its location and boundaries. To delimit and identify this area, we have a specific ESD marking tape and adhesive pictograms in our range.

- 1 - ESD mats

- 2 - Workstation with ESD coating

- 3 - Electric workstation with ESD coating

- 4 - ESD marking tape

- 5 - ESD pictogram

- 6 - ESD bracelet

- 7 - Grounding

- 8 - ESD seat

- 9 - ESD containers

Do not hesitate to explore our new ESD products to discover all our solutions to equip your company and protect you from the risks of ESD.

DOWNLOAD THE STAINLESS STEEL/ESD GUIDE

Optimize your processes and improve your performance !

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.