ESD products

As close to the field, our observations and analyses have led us to create a range of ESD products. Indeed, the damage caused by electrostatic discharges, even of low voltage, generate significant non-quality costs for the customer as well as for the manufacturer. These phenomena are invisible and difficult to detect on finished products. They affect in the more or less long term the reliability of the product by deteriorating sensitive components.

What is ESD?

ESD is the abbreviation for "Electro Static Discharge". Static electricity discharges are physical phenomena that occur every day when two bodies are charged differently. One unloads on the other. The term is often used in industry to describe unwanted stealth currents that can damage electronic equipment.

Why set up an EPA work zone

While most of the time, these discharges go unnoticed and are harmless to humans (90% of electrostatic discharges are less than 3000 V), the effect they can have on hardware, electrical or electronic components such as semiconductors is disastrous. The cost of failures caused by ESD is estimated at several million euros in France per year. These costs include claims, diagnostics, repair costs, loss of image of the company.

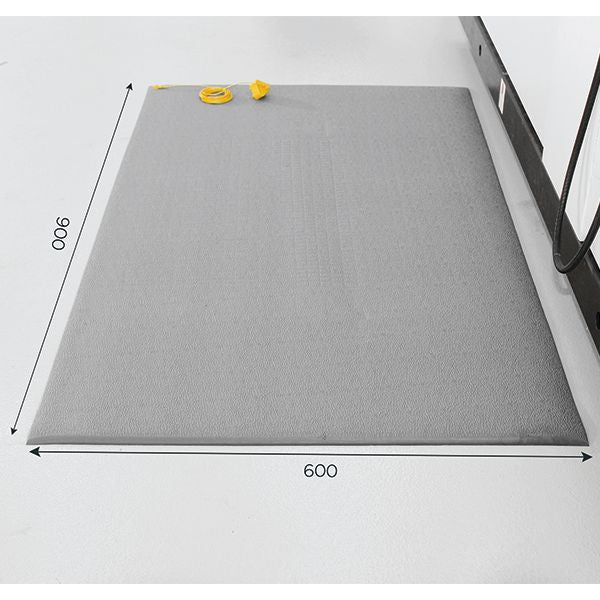

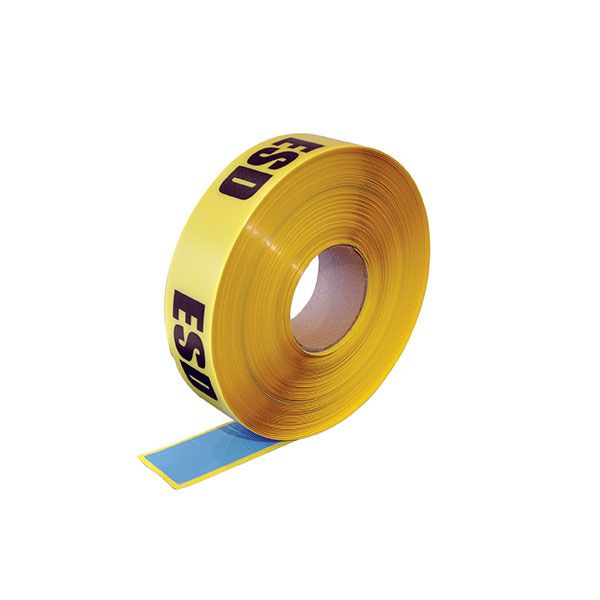

This is why when the risks of electrostatic dischargehave identifieds, it is important to put in place preventive measures. It is recommended to install EPA (Electrostatic Protected Area) work zones: it is a delimited area protected from electrostatic discharge. This area can be a worktop, an island, a room, or even a building. Only persons authorized and equipped with grounding devices (bracelets, shoes or heels, appropriate work clothes) are admitted to this zone. The ideal solution is to provide: on the ground, an ESD coating or mat on which the operator can be unloaded, asemiconductor workstation by its nature or equipped with one or more ESD coatings as needed, abracelet-type device that the operator will wear tightly on the wrist and a connection to the ground. The EPA must present signage that clearly identifies its location and boundaries. To delimit and identify this area, we have in our range a specific ESD marking strip and adhesive pictograms.

Do not hesitate any longer and discover now our range of ESD products for all demanding environments.