300 novelties

to fully satisfy you

LEAN tools and approaches

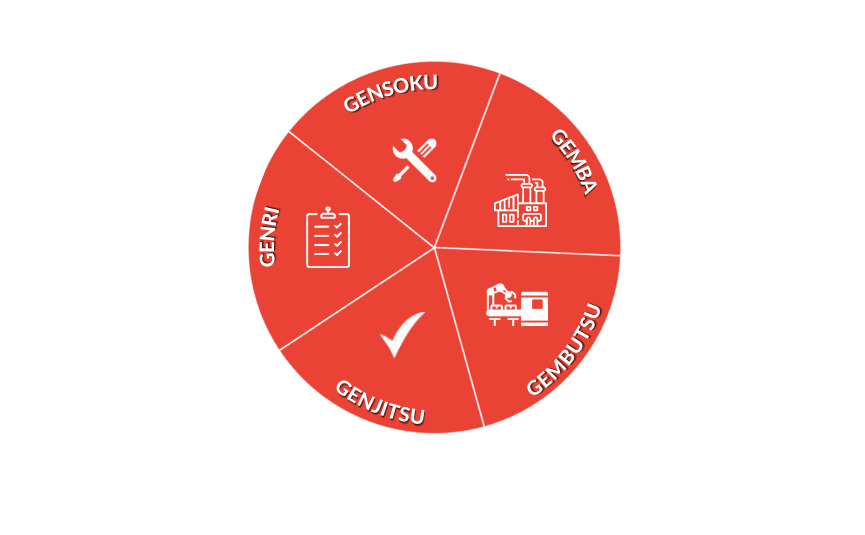

The continuous improvement often promoted by Lean Management can be illustrated by the Japanese 5G theory. QRQC has a similar approach in a sense that it focusses on the response's effectiveness and relevance to problems. In a few words, the goal of the 5G is to be able to combine theory (standards) and practice (the reality on the ground). To do this, managers or leaders must regularly go to the places of activity and production, where the value is created. 5G is not just about solving problems, however, it is a real approach that helps to sustain good practice in a company.

Like the 5S, which we owe to Toyota, the 5Gs correspond to a succession of steps to be followed in order to overcome certain errors/problems. The aim of the 5Gs is to reconcile theory and practice and to answer the following questions:

The answers to these questions can be found by applying the 5Gs:

This is the place where the work and analysis take place. For example, in an industrial context, this is often a production centre. The goal of the Gemba is to go there to analyse and observe the working environment. In this way, the managers/leaders/directors will gain a better insight into the reality of their company, in terms of their internal processes and organisation. Indeed, a major benefit of the Gemba is that it can quickly bring to light the problems that an operator may be facing. In a sense, this stage is very similar to an audit: a theme must be chosen, the employees must be informed and be aware of the audit methods, etc. The Gemba focuses on the processes rather than on the individual. The aim is to be able to identify the value chain to get as close as possible to the core of the activity, and thus to identify the aspects that may pose the most difficulties. To learn about the Gemba, the company's decision-makers must visit the workshops/production centres to be able to use it in their analysis and decision-making.

The Gembutsu is part of the Gemba: it is a search for "concreteness". The "Genchi Gembutsu" can be translated into French by: "to go and see for oneself" or "object that one can touch" depending on the translation. The aim is for decision-makers in a company to have first-hand knowledge that they can only acquire by going out into the field. Gembutsu focuses more on the specifics, the detail that is found in the field. Thus, the aim is to deal specifically with a problem relating to a piece of equipment, a product, etc. This can be done through workshop integration days, participation in a production process, etc. Some companies now use "24 hours in my skin" days to develop internal knowledge of the company, between departments.

Real facts. This is the data and information that managers/leaders can collect when they are in contact with the field. Ideally, they should base their decisions only on what they have seen with their own eyes or what first-level staff have been able to share as information.

While the 5G method emphasises the practical side of its approach, it does not ignore the theoretical aspect. Genri simply intends to take into account the available information/documentation. At this stage, it is a matter of studying the procedures and standards in place to assess their relevance and whether they are really applicable. This provides a framework for previous 3Gs that need a minimum of organisation to be effective.

Once again, the standards in place must be weighed against the reality on the ground. Thus, corrective measures can be put in place to change standards that are ill-adapted or even obsolete. An internal communication plan can also be envisaged to make the whole company aware of the procedures and habits to be put in place. This makes it possible to increase the commitment of each operator/collaborator to their work. At this stage, it is also a question of closely monitoring the transformations that the company is carrying out to be able to give advice based on information gathered directly on the ground. In order to go deeper, companies can use a Plan Do Check Action scheme to quickly overcome any difficulties that arise.

The first results naturally concern the handling of problems and unforeseen events on a production line, in a workshop. The 5G method requires managers or leaders to go out into the field quite regularly to be as reactive as possible. Overall, Toyota's 5Gs are part of a real logic of production process optimisation.

5G is a management method. It is particularly present in the large Japanese industrial groups which still apply this method. This method makes it possible to maintain a particularly strong bond of trust between managers/leaders and operators. The contacts that managers have with the field are intended to be as constructive and not as 'negative' as possible. When a manager visits a workshop, it is not to punish an operator for not applying this or that standard perfectly. The manager's aim should be to discuss with this person to understand the reality of the tasks he or she is carrying out, to put them into perspective with the standards in place, and to correct them if necessary. Companies that apply a "5G method" must assume that improvements are about processes and standards. Often, human errors/bad working methods are due to inadequate standards or limited access to information.

This bond of trust is only acquired over the long term, but it increases the company's responsiveness and the involvement of its employees. With 5G, employees feel more considered and listened to.

Although less common, companies can apply this management model to their administrative departments or support functions. It works in exactly the same way.

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.