STAINLESS STEEL: An ideal protection solution against electrostatic discharges and necessary in certain specific environments

STAINLESS STEEL: An ideal protection solution against electrostatic discharges and necessary in certain specific environments

DOWNLOAD THE STAINLESS STEEL/ESD GUIDE

What is an electrostatic discharge and why should you avoid it?

An electrostatic discharge (or ESD) is a flow of electric current that occurs when two objects with different electrical potentials meet. One of the two objects will then discharge onto the other. In concrete terms, this is the famous electric shock that we have all felt when touching a metallic surface or opening a car door. This phenomenon is all the more remarkable when you brush your hair or rub a balloon on your head. While this sensation is unpleasant for a human being, it is usually not dangerous. In electronics, on the other hand, this is a serious problem, as the components are always smaller, and an electrostatic discharge can seriously damage or even destroy the component. This leads to non-quality costs, as the component is either unusable or has a hidden defect. The problem is that this phenomenon is invisible and therefore very difficult to detect. The best solution is still to protect yourself from it.

How to protect yourself?

Once the risks have been identified, it is important to implement preventive measures. The international standards EN 61340 Part 5-1 and EN 61340 Part 5-2 present the general requirements and user guide for the protection of electronic devices against electrostatic processes.

The rule is simple: No charging ➔ No discharging

It is therefore necessary to:

- Reduce load creation through earthing or equipotential bonding

- Remove all unnecessary insulating materials or neutralize essential insulators with ionizers

- Protect products by using packaging certified for transport outside the EPA (Electrostatic Protected Area)

An ESD control plan should be established in which you will define:

- What you wish to protect (product, process, area, etc.)

- How you wish to protect it (grounding, necessary equipment, signage, PPE, personnel, training, etc.)

- How you will ensure the conformity of the measures (controls)

The work environment

- Industry standard environment : For a standard environment, we offer a whole range of products on aluminium frames with painted sheet metal bottoms and laminated or epoxy painted steel tops that we can equip with ESD devices.The electrostatic charge is evacuated via a specific coating dimensioned for SESA SYSTEMS stations and laid in our workshop and an earthing cable. We also have grounded wristbands to eliminate the electrostatic charges coming from people working in this environment, which are the main source of charge

- Specific environment: For a specific environment, food or pharmaceutical, our INOX range meets the requirements in terms of ESD protection.

Why is stainless steel so popular with food manufacturers?

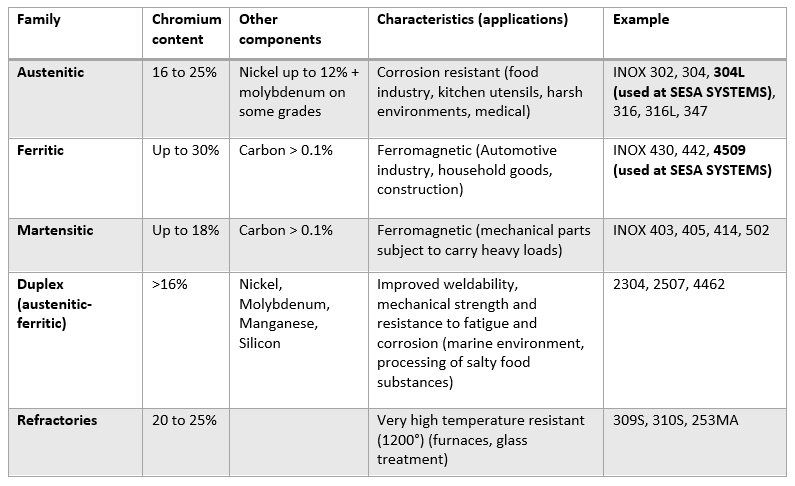

Stainless steel is a steel alloy with more than 10.5% chromium, which is not very sensitive to corrosion.

There are several families of INOX, each with specific characteristics:

Stainless steel 304 L is an acid-resistant 18/10 austenitic Cr-Ni alloy steel with good anti-corrosion properties due to its reduced hydrogen content. It is approved for temperatures up to 300 degrees Celsius. INOX 304 L is resistant to water, steam, atmospheric humidity and food acid, as well as to weak organic and inorganic acids, and is very versatile in its application possibilities: food industry, beverage production, pharmaceutical and cosmetic industries, apparatus construction for chemistry and medicine.

The criteria for suitability for food contact are described in the following texts:

- The standard NFA 36 711 " Stainless steel intended to come into contact with foodstuffs, products and beverages for human and animal consumption (excluding packaging)".

- NSF/ANSI 51 Requirements - International Standard Edition 2009 for "Materials for Equipment and F.D.A. Materials. (United States Food and Drug Administration) requirements for materials intended to come into contact with food.

Austenitic stainless steel therefore already has ideal characteristics for ESD (Resistivity: 73x10-8 Ωm).

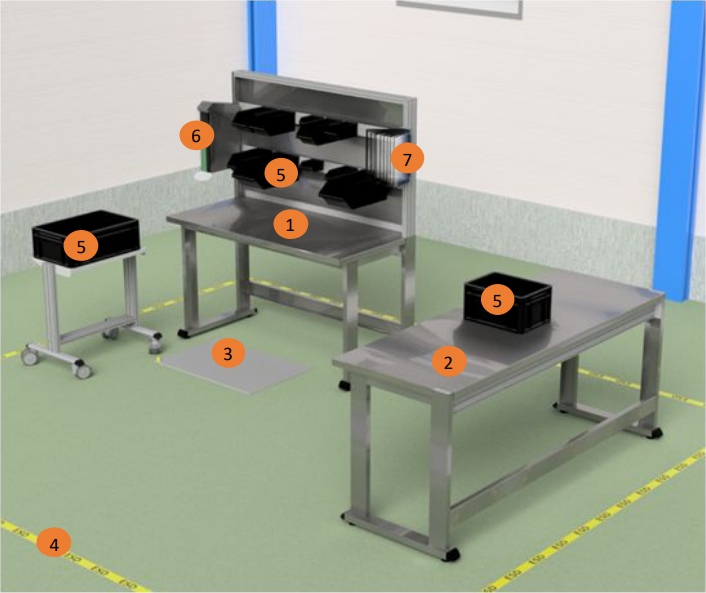

- 1 - QUALIPOST 3500 INOX with bottom L1564

- 2 - QUALIPOST 3500 INOX bottomless L1992

- 3 - ESD mats

- 4 - ESD marking tape

- 5 - ESD bins

- 6 - DOCAPOST 250 INOX

- 7 - DOCAFLEX INOX with antistatic folders

DOWNLOAD THE STAINLESS STEEL/ESD GUIDE

Optimize your processes and improve your performance !

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.