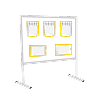

Digitalization to Boost Your Industrial Performance

Unlock the full potential of your workshop!

Digital solutions to optimize your meetings, streamline your processes,

and enhance your operational efficiency.

Our Lean Enterprise 2025 product catalog is here!

- Brings together all SESA SYSTEMS products

- Discover our new products for 2025

- Contains all our ranges

- 364 pages of innovation

- Totally free catalog

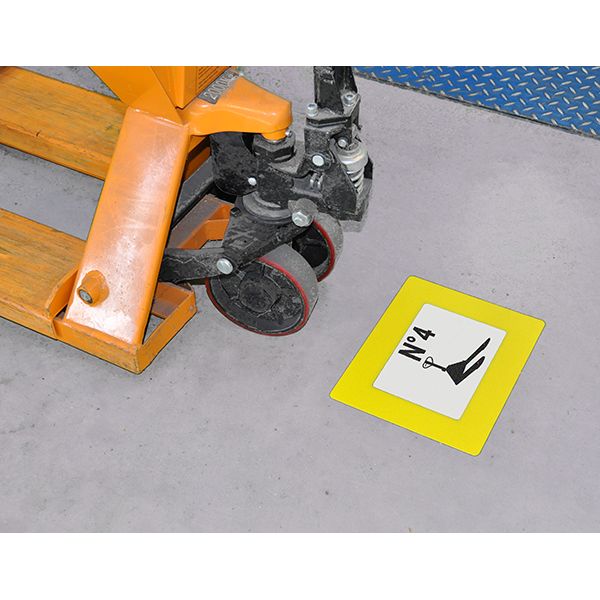

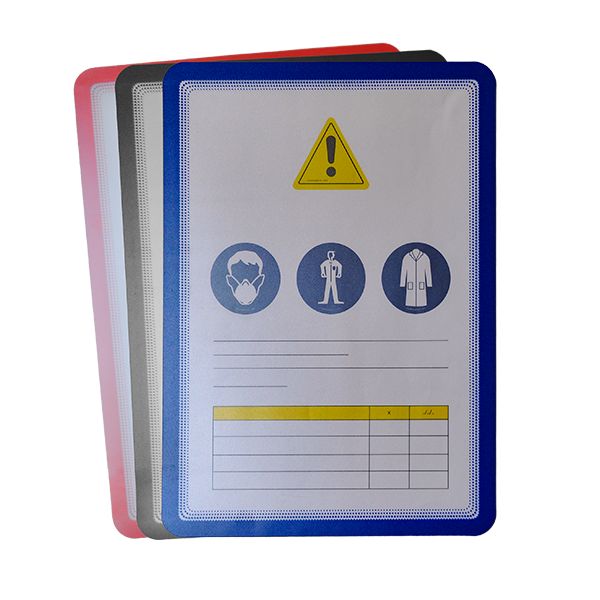

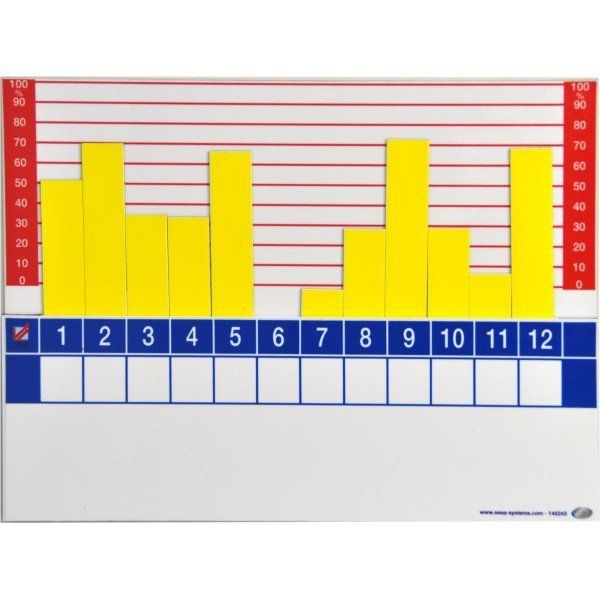

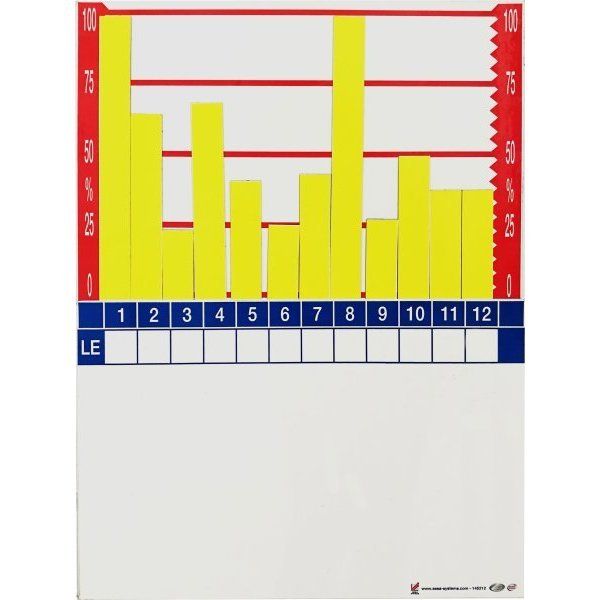

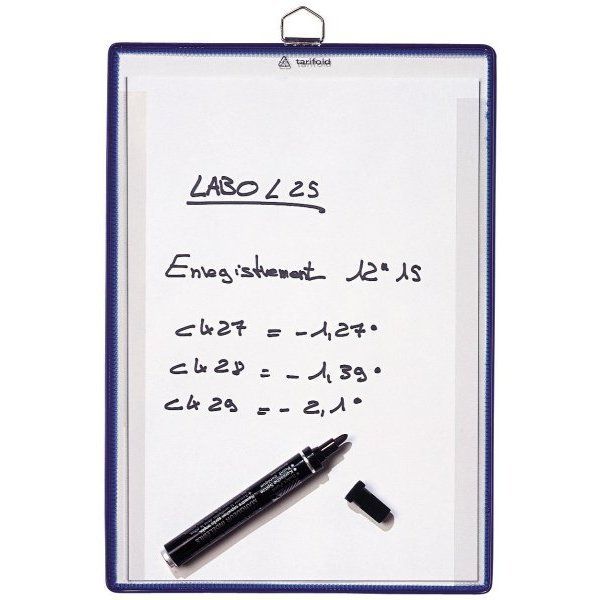

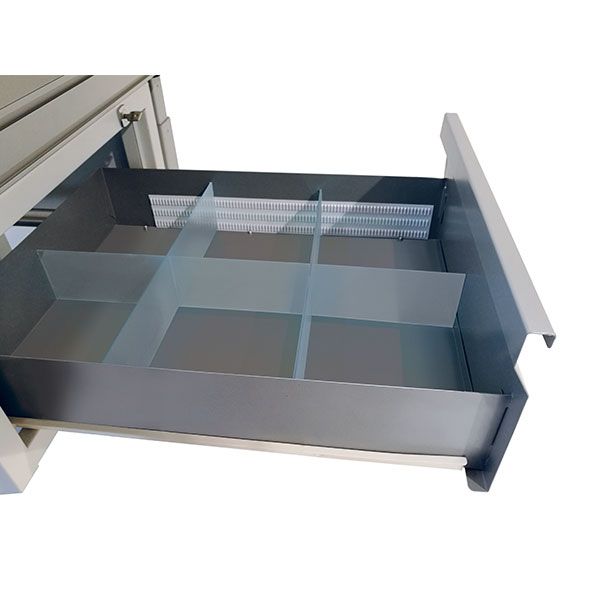

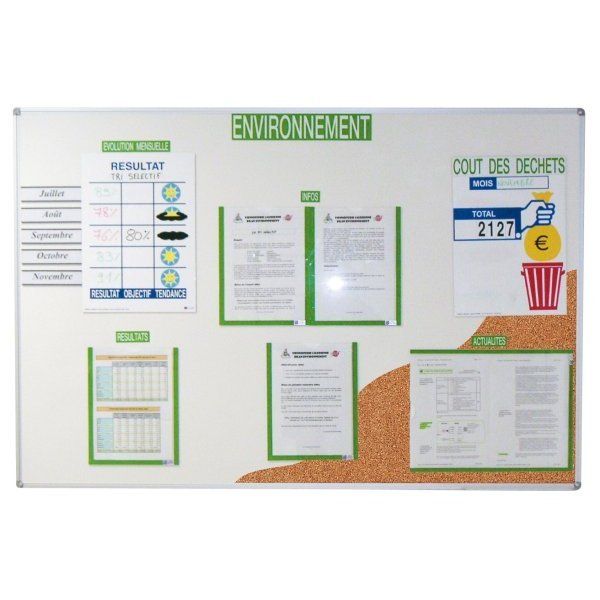

Adopt 5S!

✅ Immediate reduction in waste

✅ Enhanced safety and compliance

✅ Clear and productive workspaces

✅ Sustainable standardisation

✅ Continuous improvement

LEAN Manufacturing and Visual Management Expert

Find all the LEAN webinars presented by SESA SYSTEMS.

SESA SYSTEMS is an expert in Lean Management, Lean Manufacturing, and Lean Office. We regularly present new webinars to develop these topics. To help you keep up with the latest LEAN news and find the keys to implementing the different LEAN methods, discover our webinars now. Watch past webinar replays for free!

Our LEAN advice and methods

Lean is a method based on the pursuit of performance through continuous improvement and the elimination of waste. This allows teams to move forward together toward a common goal more efficiently, enabling employee development while strengthening the company.

SESA SYSTEMS ACADEMY

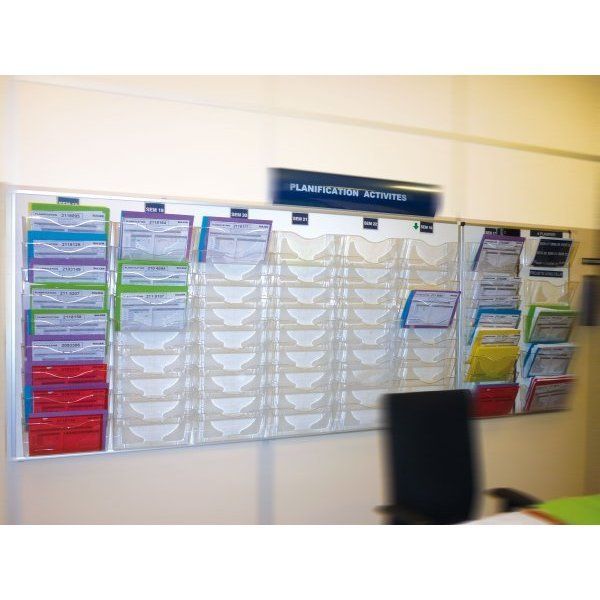

SESA SYSTEMS ACADEMY, a true think tank in the form of a showroom displaying all LEAN Enterprise and Visual Management products.

Follow us on LinkedIn!

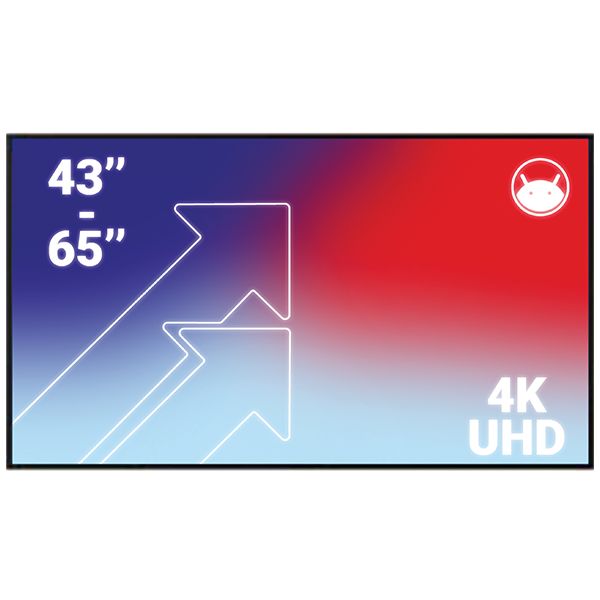

"We chose SESA SYSTEMS' E-MEETING interactive screens for our performance animation meetings on our different production site levels. In addition to the premium quality of these screens, which is an important criteria, the support provided by the SESA SYSTEMS teams for training and handling was very much appreciated. I am satisfied with the E-MEETING screens."

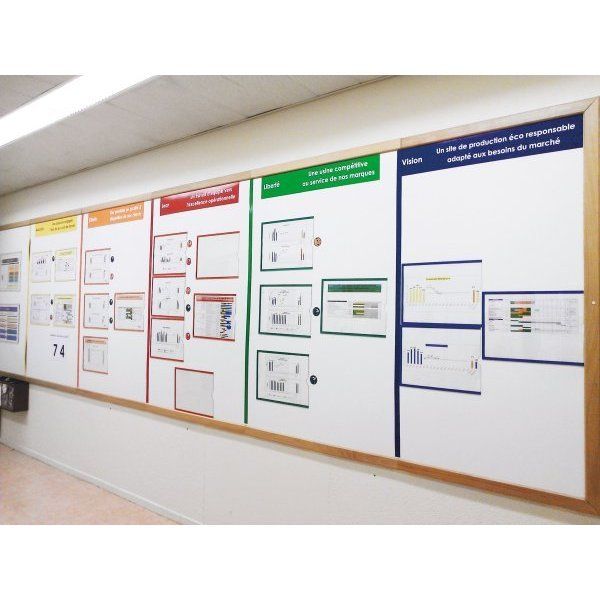

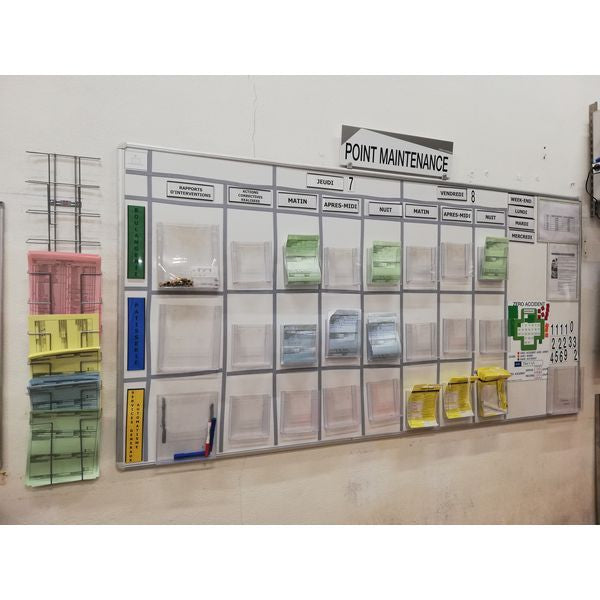

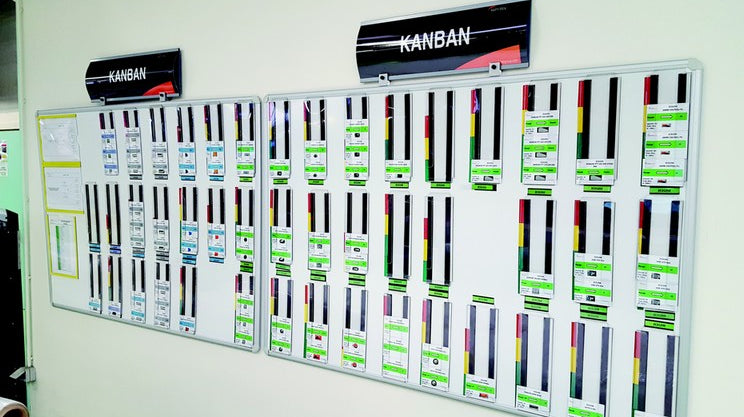

"Since 2016, SESA SYSTEMS has been assisting us with the reorganization of our work areas. Robustness, adaptability, modularity, visuals and ergonomics are SESA SYSTEMS' products strong points. Visual Management assists the operators in their daily tasks and the company's visual marketing during customer visits."

"SESA SYSTEMS supports you in the deployment of your LEAN ACADEMY. The advice, follow-up, and quality of the products are services for which I am very happy."

"We came to the SESA SYSTEMS ACADEMY as part of a project to fit out a logistics workshop. This space gave us a maximum of ideas, the installation of the products corresponds perfectly to our expectations. I am satisfied with SESA SYSTEMS products."

"Genuine products for the working world. Useful solutions unmatched by other competitors."

"Exclusive and quality products, a must on our way to continuous improvement."

"SESA SYSTEMS is supporting us in the redesign of the various packaging work areas. The support in choosing the best workstation allowed us to improve ergonomics thanks to the modularity; robustness is a strong point of SESA SYSTEMS products. Visual management supports operators in their daily tasks, and the company's marketing visuals are used during customer visits."

"For about 10 years, we have been working with SESA SYSTEMS, our Visual Performance Management provider. SESA SYSTEMS has equipped us with communication points and ergonomic workstations to improve our LEAN practices. Our initial experience with E-MEETING has allowed us to move toward an Industry 4.0 vision to manage, disseminate, and centralize all our indicators. The SESA SYSTEMS sales team is attentive and responsive to our needs. We recently had the opportunity to participate in an ACADEMY to discover SESA SYSTEMS' expertise."

"As part of the development of a new industrial building, SESA SYSTEMS was able to understand and respond to our needs. We benefited from personalized support provided by a business manager who presented and advised us on all the product ranges and a tailor-made definition for our project, while respecting our specifications. Several visits and workshops were able to be carried out in your showroom."

Latest news

View allHow to Improve Production Line Performance: Solutions and Best Practices

Occupational therapy and industry: practical solutions to improve health and well-being at work

Occupational therapy and industry: discover practical solutions to prevent MSDs and improve workplace health through appropriate ergonomic equipment.

How to Avoid Production Delays? 5 Keys to Optimize Planning

Manufacturer of industrial furniture, LEAN Manufacturing equipment and Visual Management

SESA SYSTEMS, an industrial furniture manufacturer, was founded by Jean-Paul Lerailler in 1990. Developing innovative products from our inception to the present day, we have continually revolutionized the work of operators. After creating the first QUALITY POINTS and developing a complete range of Visual Management products, SESA SYSTEMS began developing tools dedicated to LEAN Manufacturing.

In 2018, SESA SYSTEMS embraced the digital revolution, notably through the development of SESAHUB. As a manufacturer of industrial furniture, we are proud to count the largest industrial groups among our customers. All of our products are recognized and marketed internationally. Innovation is at the heart of our business, and we already have 8 patents and 240 registered designs, with nearly 150 new products released each year.

Since 2024, SESA SYSTEMS has been a mission-driven company that supports its clients in their LEAN projects through innovation and the manufacturing of the best products to serve people and their environment.