Gain efficiency with Lean management tools

Gain efficiency with Lean management tools

Lean Management is a production management method that effectively improves the performance of your business

DOWNLOAD THE LEAN ENTERPRISE CATALOGUE

What is LEAN MANAGEMENT?

Historically, born in Japan in the automotive industry, more precisely within the Toyota production system in the 1970s, Lean management is a production management method that has the principle of effectively improving the quality and profitability of your company: productivity, cost control, delivery time, development of all employees.

The definition of "Lean" being "lean" or "fat-free" focuses on reducing sources of waste, in order to gain in performance. This is a prerequisite for identifying opportunities to improve production processes in the company. The main objective should not be to focus on reducing financial costs, but to develop an approach from the field as close as possible to the company's employees and collaborators.

Lean is mainly a method used in industry (the automotive industry in particular), but is nevertheless adaptable everywhere regardless of the sector and size of the company. Lean is mainly a method used in industry (the automotive industry in particular), but is nevertheless adaptable everywhere regardless of the sector and size of the company. Lean impacts all levels of the company and requires cooperation from all departments.

What are the principles of Lean management in companies?

The principle of this management technique is the search for performance while satisfying the customer.

In companies, the LEAN model aims to eliminate the 3 main enemies of work organization:

-

MUDA

Waste that does not add value to the product (what ends up in the trash, breakdowns, unnecessary travel, waste of time, things that are added to the product, but that the customer does not want, etc.).

-

MURI

Excess, overload of work caused by unsuitable processes (personnel, when the workload is not adapted to the number of workers; installations, when the load is greater than what an installation can do (its capacity); stocks, when parts or products do not "turn".

-

MURA

Variability, or irregularity (machines that do not always take the same time to do the same thing and whose quality varies; operators who do not all and not always do the same work when assigned to the same position; suppliers who do not always deliver the same quantities of raw material).

Lean management particularly tackles seven sources of MUDA in a company: overproduction, delays, waiting, unnecessary stocks, handling and transport activities, superfluous treatments, unnecessary movements (productive or administrative), to which must be added an eighth waste, which is the non-use of the intellectual resources of the staff. To effectively implement Lean Management and therefore, change in the company, there is a range of model tools and methods at your disposal:

KANBAN

SIZE AND CONTROL STOCKS ACCORDING TO ACTUAL AND FORECAST CONSUMPTION

Objectives: to obtain a Just-in-Time or "5 zeros" organization. The five zeros correspond to "zero failure", "zero delay", "zero paper", "zero stock" and "zero defects".

KAIZEN

SMALL STEP FOR GREAT PROGRESS

Approach based on small constant improvements, day after day. It is a gradual and gentle method. KAIZEN encourages a process-oriented way of thinking. If the results are not compliant, it is clear that the process is not compliant and management will invest in identifying and correcting process problems.

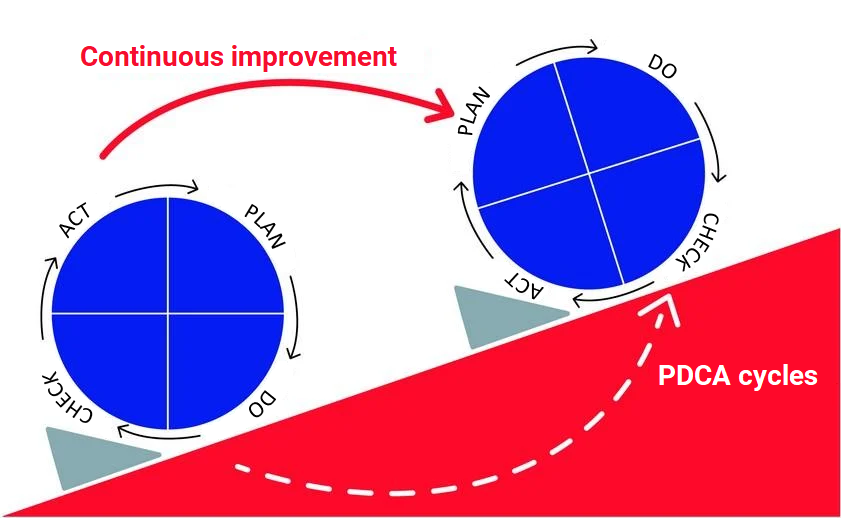

PDCA

PROBLEM SOLVING: PLAN DO CHECK ACT

Symbolized by a wheel called "The Wheel of Deming" referring to William Edwards Deming. Like a virtuous circle, the Deming wheel is a process with cycles and a sequence between each step. Its purpose is to improve the processes within a company, a department, a team etc.

5S

ORDER AND DISCIPLINE

Seiri, Seiton, Seiso, Seiketsu, Shitsuke is a practice of optimizing working conditions and environment, working time by ensuring that this environment remains tidy, cleaned, secure, by establishing rigor.

SIX SIGMA

BLACK BELT IN STATISTICS

Objective: to improve the efficiency of the company's processes through the analysis of customer needs (through surveys and satisfaction questionnaires) and sales and production statistics.

Why do Lean Management?

Lean puts the customer and the employee at the heart of the company. It is a real business project aimed at improving performance while improving the working conditions of employees. To achieve change, Lean mobilizes the company's actors in the field, including and especially managers.

This type of management has advantages, but also disadvantages

The Lean management method is mainly based on the continuous improvement of workflows in the company:

- Reduce waste of all kinds that cost unnecessarily and hinder processes,

- Manage manufacturing and marketing costs more efficiently,

- Increase the level of just-in-time by streamlining production flows according to customer expectations,

- Optimize the communication and training of employees in the company,

- Motivate employees by consulting them and involving them in changes,

- Promote the autonomy and responsibility of employees using the agile method,

- Reassure customers and other interested parties.

Despite the attractive prospects of increasing the company's productivity, we must not forget that Lean Management is thought of in the long term and impacts all the actors of the company.

In addition, it is important not to neglect the health of employees in favor of increasing at the risk that they feel tired, stressed or have a drop in morale. It is essential that everyone can, without constraint, find their place and their role in the long term. In addition, an employee doing useful and impactful work within the company, rather than on worthless busy work, has a better sense of purpose.

Industry 4.0 to facilitate your Lean management

In the digital age, new technologies are an asset for the organization of the company. They bring an improvement of service, tool, work for all the stakeholders of the company. SESA SYSTEMS has a considerable interest in innovative products. To do this, SESA SYSTEMS supports you in your digital transformation and develops a line of innovative products to integrate the factory of the future. Facilitate your production meetings or meetings with large interactive whiteboards to have quick access to company data and make fast, shared and more efficient decisions.

DOWNLOAD THE LEAN ENTERPRISE CATALOGUE

Optimize your processes and improve your performance !

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.