Découvrez les innovations 2026

150 solutions conçues pour vous !

-

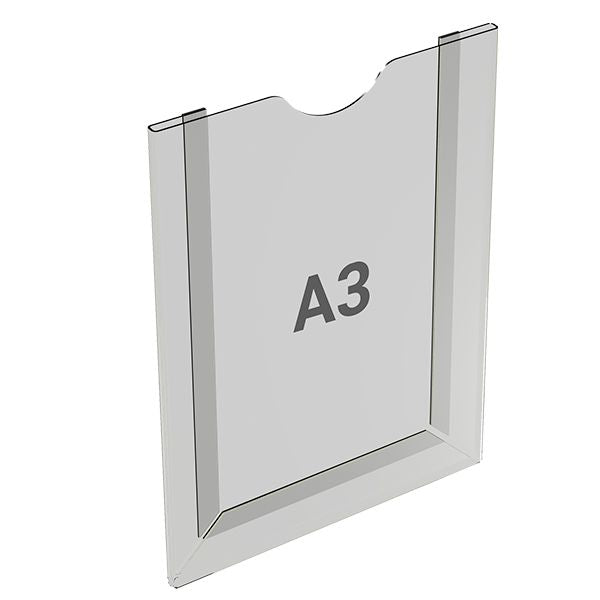

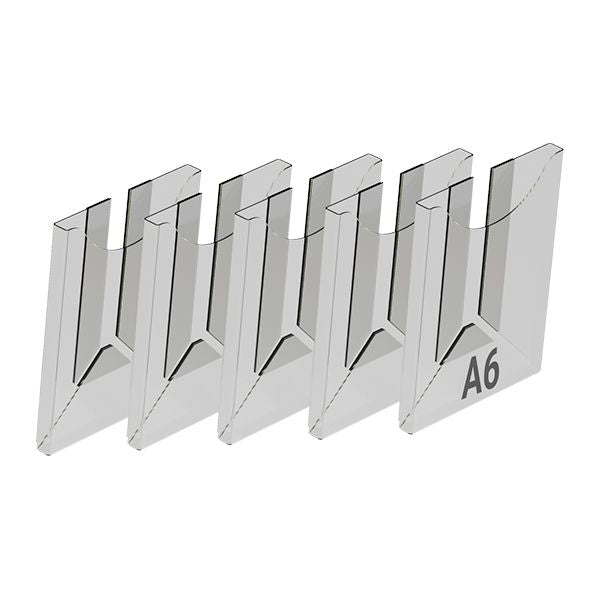

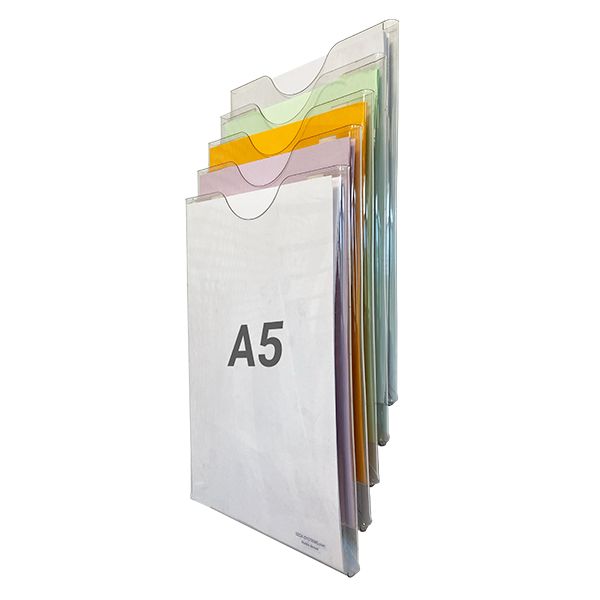

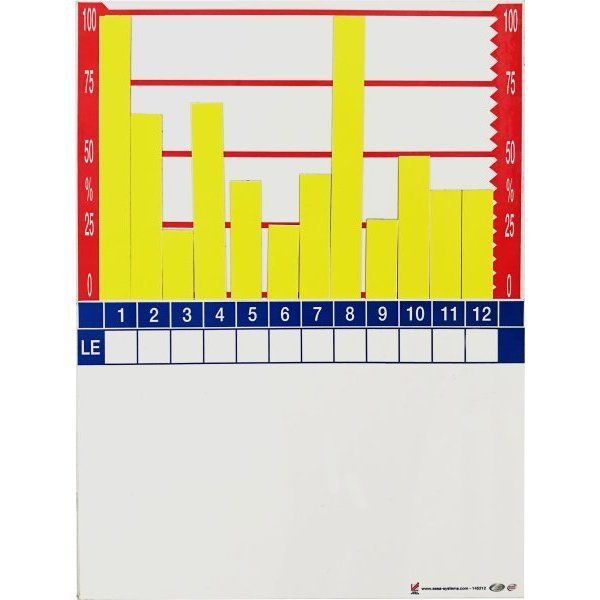

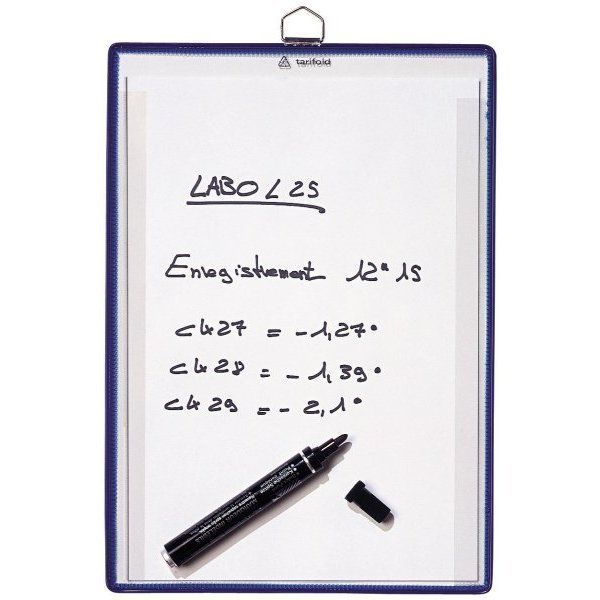

Titre du produit12,34 €

-

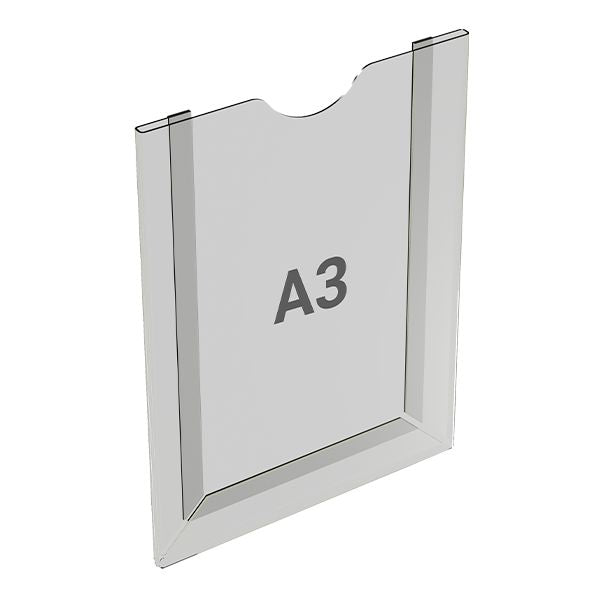

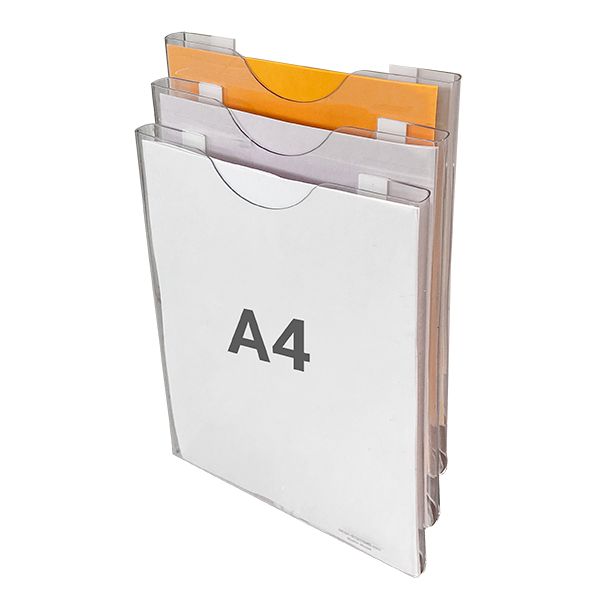

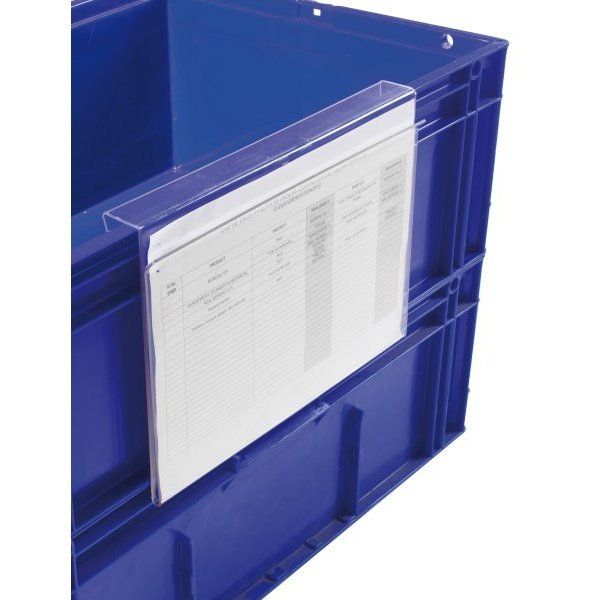

Titre du produit12,34 €

-

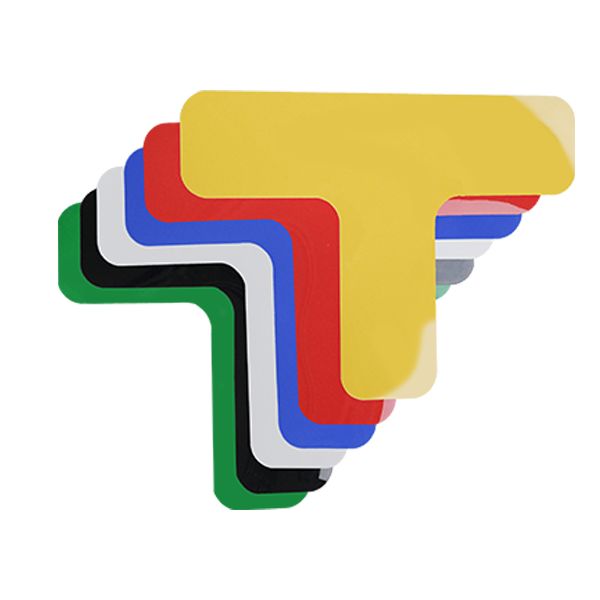

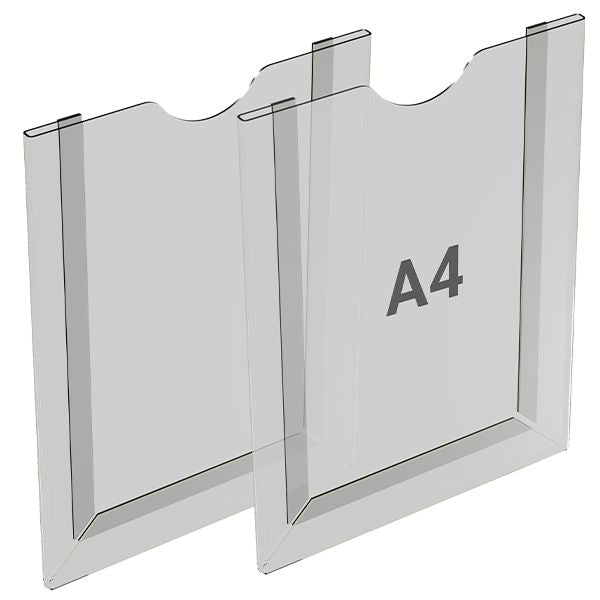

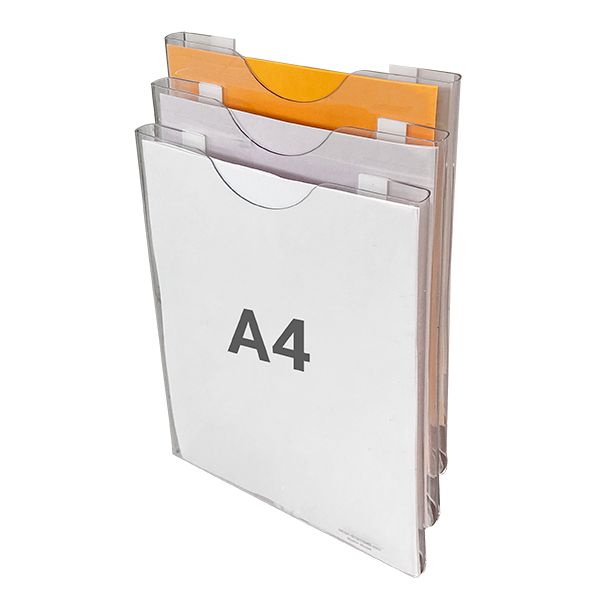

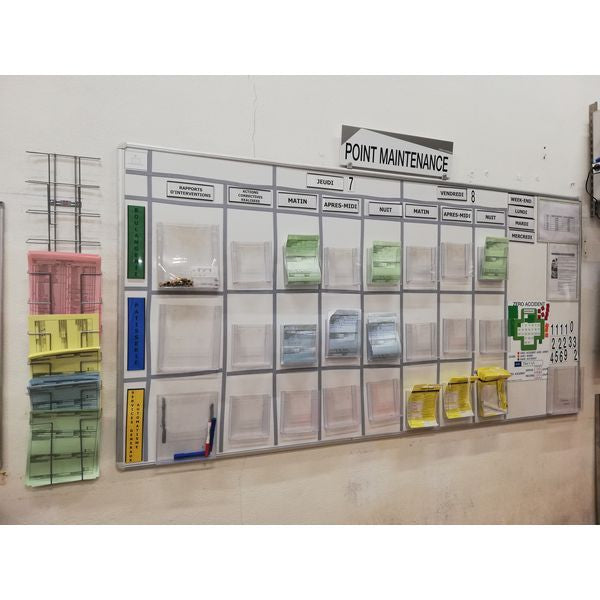

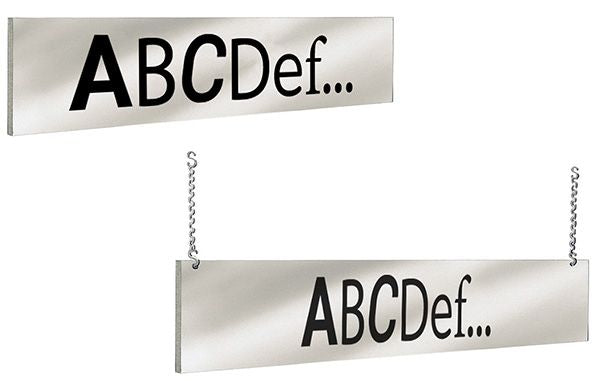

Titre du produit12,34 €

-

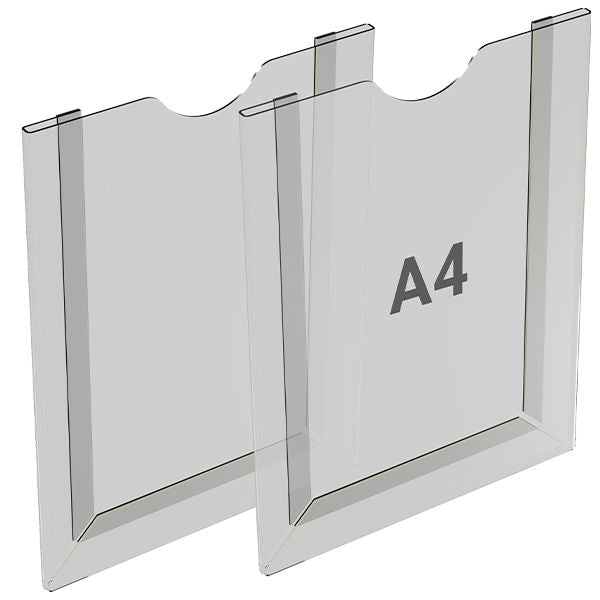

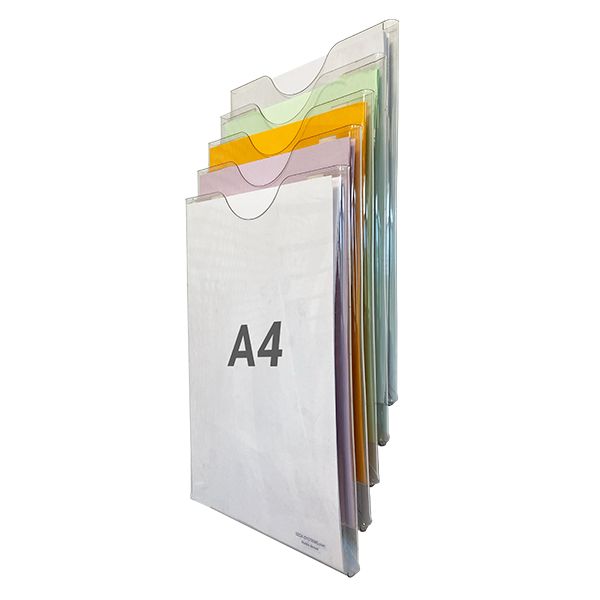

Titre du produit12,34 €

Découvrez notre catalogue Lean Enterprise 2026

- Regroupe tous les produits SESA SYSTEMS

- Découvrez nos nouveautés 2026

- Content toutes nos gammes

- 376 pages d'innovation

- Catalogue totalement gratuit

Les équipes R&D et de production de SESA SYSTEMS conçoivent et fabriquent en France des solutions innovantes en aluminium. Chaque année, nous développons de nombreux produits brevetés et modèles déposés. Notre catalogue est disponible en ligne ou par courrier.

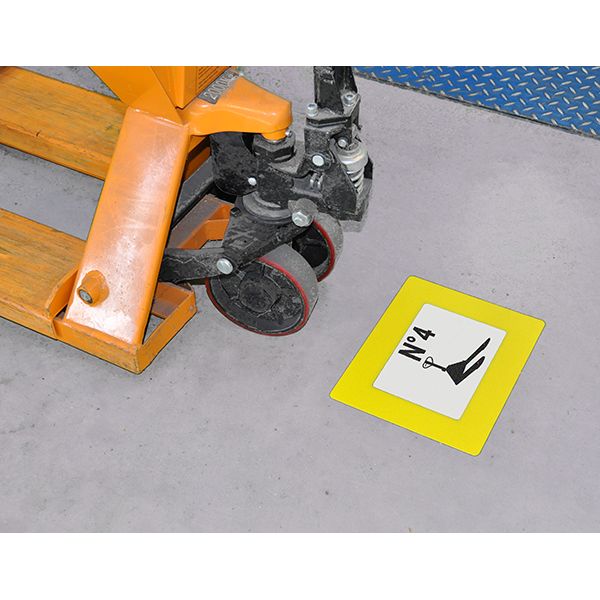

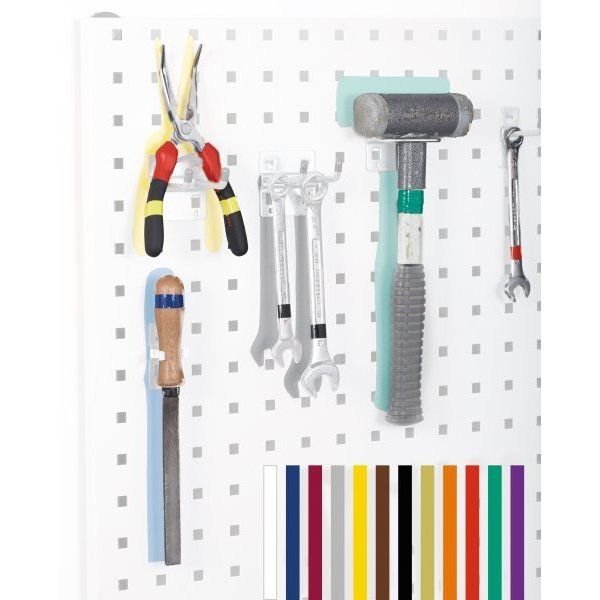

Adoptez le 5S!

✅ Réduction immédiate des gaspillages

✅ Sécurité et conformité renforcées

✅ Espaces de travail clairs et productifs

✅ Standardisation durable

✅ Amélioration continue

Comment optimiser la démarche 5S avec le digital ?

Au programme :

📚 Les principes fondamentaux de la démarche 5S et le suivi dans la durée

🔎 Comment améliorer vos pratiques de pérennisation du 5S avec le digital

💬 Les étapes et les bénéfices de la digitalisation des flux de l’entreprise

🚀 Quelques conseils pour réussir avec des exemples

❓ Session questions/réponses : échangez directement avec nos experts et nos utilisateurs.

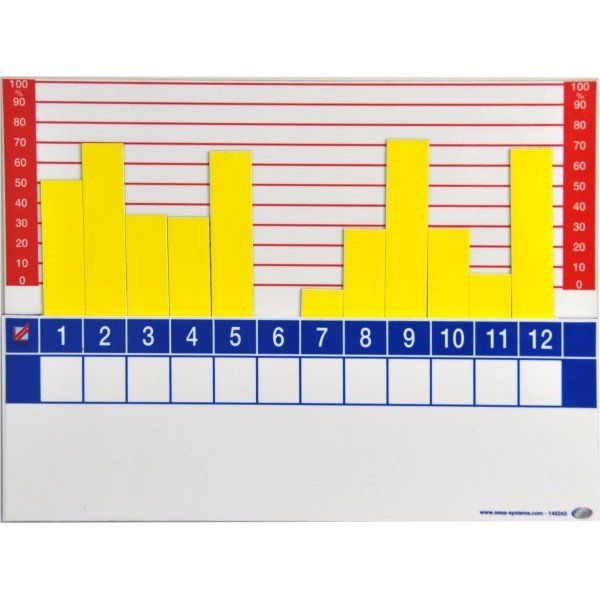

Nos conseils et méthodes LEAN

Le Lean est une méthode qui repose sur la recherche de la performance grâce à l’amélioration continue et l’élimination des gaspillages. Cela permet aux équipes d’avancer ensemble vers un même but et de manière plus efficace, permettant le développement des collaborateurs tout en fortifiant ainsi l’entreprise.

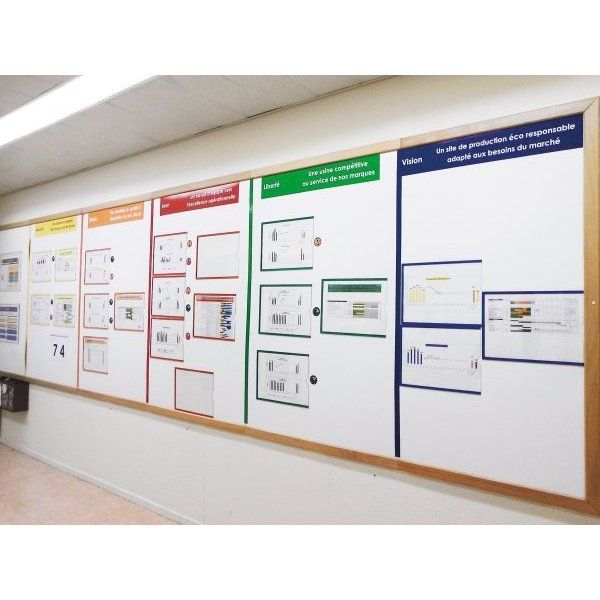

SESA SYSTEMS ACADEMY

Vous souhaitez améliorer votre organisation LEAN ? Visitez la SESA SYSTEMS ACADEMY, un véritable laboratoire d'idées sous forme de showroom avec exposition de l'ensemble des produits du LEAN Entreprise et du Management Visuel. Réservez votre place pour vous ou votre entreprise dès maintenant.

Suivez-nous sur LinkedIn !

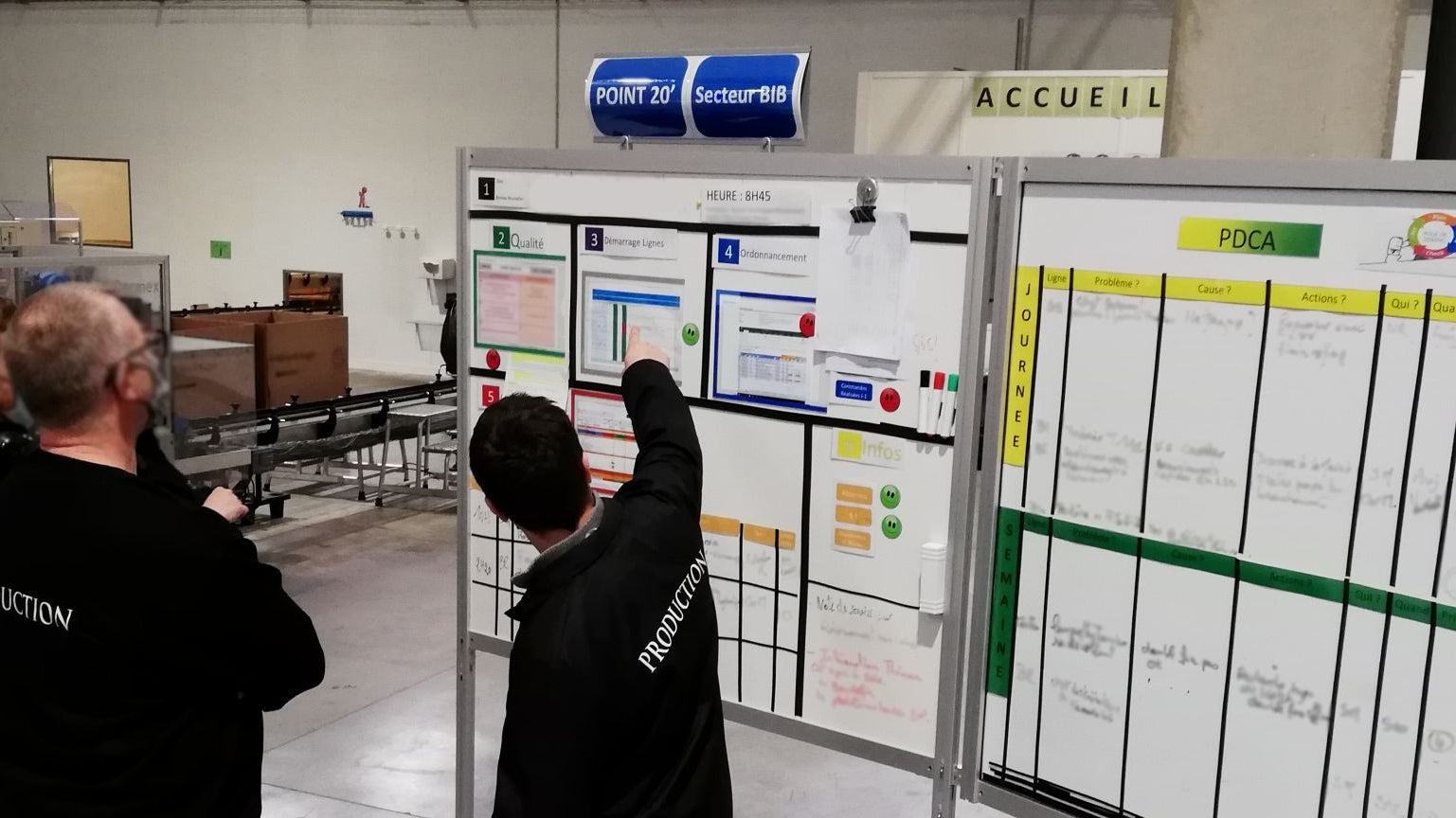

"Nous avons choisi les écrans interactifs E-MEETING SESA SYSTEMS pour l’animation de nos réunions de performances au sein des différents niveaux de notre site de production. Au-delà la qualité premium de ces écrans qui est un critère important, l’accompagnement des équipes SESA SYSTEMS pour la formation et la prise en main des écrans fut très appréciée. Je suis satisfait des écrans E-MEETING."

"Depuis 2016, SESA SYSTEMS nous accompagne sur le réaménagement des zones de travail. La robustesse, l’adaptabilités, la modularité, le visuel et l’ergonomie est un point fort des produits SESA SYSTEMS. Le management visuel accompagne les opérateurs dans les tâches quotidiennes et le visuel marketing de l’entreprise lors des visites clients."

"SESA SYSTEMS vous accompagne dans le déploiement de votre LEAN ACADEMY. Le conseil, le suivi, et la qualité des produits sont des services pour lesquels je suis très content."

"Nous sommes venu à la SESA SYSTEMS ACADEMY dans le cadre d’un projet d’aménagement d’atelier logistique. Cet espace nous a donné un maximum d’idées, la mise en place des produits correspond parfaitement à nos attentes. Je suis satisfait des produits SESA SYSTEMS."

"Des produits authentiques pour le monde du travail. Des solutions utiles inégalées par d'autres concurrents."

"Des produits exclusifs et de qualité, un impératif sur le chemin de l'amélioration continue."

"SESA SYSTEMS nous accompagne sur le réaménagement des différentes zones de travail de conditionnement. L’accompagnement sur le choix du meilleur poste de travail nous a permis d’améliorer l’ergonomie grâce à la modularité, la robustesse est un point fort des produits SESA SYSTEMS. Le management visuel accompagne les opérateurs dans les tâches quotidiennes et le visuel marketing de l’entreprise lors des visites clients."

"Depuis 10 ans environ, nous collaborons avec SESA SYSTEMS qui est notre fournisseur en terme de Management Visuel de la Performance. SESA SYSTEMS permet donc de nous équiper de points communication ainsi que de postes de travail ergonomiques dans le but d’améliorer nos pratiques LEAN.Une première expérience avec le E-MEETING nous permet de nous projeter vers une vision d’industrie 4.0 afin de piloter, diffuser et centraliser tous nos indicateurs. L’équipe commerciale de SESA SYSTEMS est à l’écoute et réactive à nos besoins. Dernièrement, nous avons eu l’opportunité de participer à une ACADEMY afin de découvrir le savoir-faire de SESA SYSTEMS."

"Dans le cadre d’un aménagement d’un nouveau bâtiment industriel, SESA SYSTEMS a su comprendre et répondre à nos besoins. Nous avons bénéficié d’un accompagnement personnalisé opéré par une chargée d’affaires qui nous a présenté et conseillé toutes les gammes de produit et une définition sur-mesure pour notre projet, tout en respectant notre cahier des charges. Plusieurs visites et workshops ont pu être réalisés dans votre showroom."

Dernières actualités

Voir tout5 étapes pour gérer la conduite du changement en digital

Comment animer une réunion TOP 5 ?

Implanter le Lean Manufacturing en production : étapes, défis et astuces

Fabricant de mobilier industriel, d’équipement LEAN Manufacturing et Management Visuel

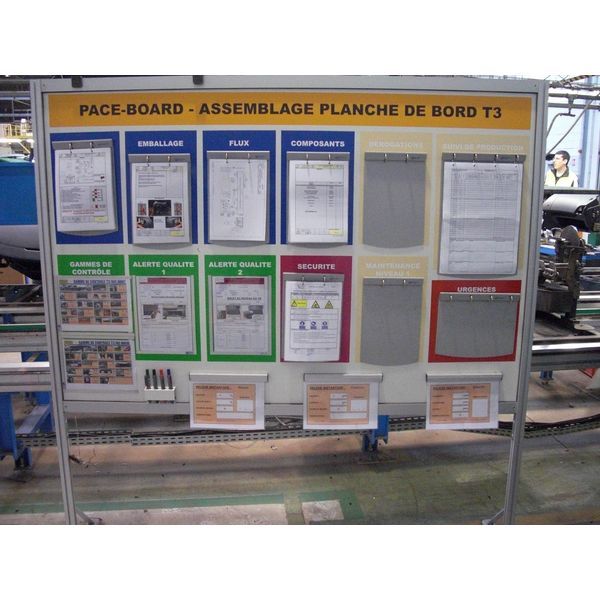

SESA SYSTEMS, fabricant de mobilier industriel, a été fondé par Jean-Paul Lerailler en 1990. Développant des produits innovants depuis notre création jusqu’à aujourd’hui, nous n’avons cessé de révolutionner le travail des opérateurs. Après avoir créé les premiers POINTS QUALITÉ et développé une gamme complète de produits de Management Visuel, SESA SYSTEMS s’est attaqué à l’élaboration d’outils dédiés au LEAN Manufacturing.

En 2018, SESA SYSTEMS prend le tournant du digital, notamment via le développement de SESAHUB. En tant que fabricant de mobilier pour l’industrie, nous sommes fiers de compter parmi nos clients les plus grands groupes industriels. L’ensemble de nos produits sont reconnus et commercialisés au niveau international. L’innovation est au cœur de notre métier et nous comptons déjà 8 brevets et 240 modèles déposés pour près de 150 nouveautés chaque année.

Depuis 2024, SESA SYSTEMS est une société à mission qui accompagne ses clients dans leurs projets LEAN par l’innovation et la fabrication des meilleurs produits au service des Hommes et de leur environnement.