Automate your production with the Internet of Things

Automate your production with the Internet of Things

The Internet of Things is a broad concept with multiple applications both personal and industrial. These applications are based on the use of data collected by connected objects communicating on a defined network.

DOWNLOAD THE INDUSTRIE 4.0 CATALOGUE

What is the Internet of Things ?

The Internet of Things is an essential component of the Industry 4.0. According to the International Telecommunication Union, the Internet of Things is defined as "a global infrastructure for the information society, enabling advanced services by interconnecting objects (physical or virtual) using existing or evolving interoperable information and communication technologies". It is therefore a network that enables information to be retrieved, stored, transferred and processed via electronic objects.

Where does the Internet of Things come from ?

The Internet of Things is the result of the mechanisation, standardisation, and automation of information processing. The concept originated in the United States in the 1980s and has been widely spread, particularly as a result of globalisation. Originally, machines were connected in a network to a server, which allowed them to be controlled. As technology evolved, connected "objects" appeared that could be identified either by an RFID chip or by an IP address. The gathering and processing of an ever-increasing amount of information allows for numerous applications, particularly in the field of decision-making and artificial intelligence.

How does it work ?

A "connected" object is, by definition, connected to a network. This allows it to interact with the network via a communication channel. This can be an RFID chip, Bluetooth, Wi-Fi, etc. In most cases, when we talk about connected objects, we are referring to the Internet network. Each object capable of communicating on this network is therefore identified by a sort of digital identity "card" which not only identifies it but also enables it to communicate with it. This is most often an IP address.

Moreover, the device on which you are consulting this page is also a "connected object" since it is connected to the Internet and has a user ID in the form of an IP address.

It is therefore thanks to this identification number that it will be possible to control and exchange with this object. This control can be done via a computer, a mobile phone and in some cases, thanks to another connected object.

What are connected objects used for in the everyday life ?

Once a connected object is installed and functional, it can receive instructions that will serve different purposes depending on the nature of the object.

The everyday applications

In concrete terms, there are a multitude of different connected objects today, including watches, televisions, cars, coffee machines, refrigerators, washing machines, personal assistants (such as Google Home or Alexa), heating systems, wood stoves, garage doors etc.

Among the most common uses is the connected watch. In addition to telling the time, it is able to collect a lot of information about your activity. So, if you go jogging, you will be able to know: your exact distance covered, your exact time, your pace, your heart rate, your top speed... This information can then be stored and compared between your different sessions to track your progress.

Let's take another example and go a step further. Your alarm clock goes off every morning at 7am, you need an hour to get ready and then catch the 8.05am train to work by 8.30am. Normally, that's enough time to get there on time. But today, all the morning trains are cancelled, so you will have to take the car, but the journey will also take longer. Plus, it's raining, and you'll have to drive slower, so you'll arrive late for work. With an ecosystem of connected objects, your alarm clock would have received information about cancelled trains in real time and would have calculated the travel time needed by car. It would then check the weather conditions in real time to see that it was raining and take this information into consideration in the travel time. With these new details, your alarm clock would have adjusted the time of your alarm to avoid being late and could even have synchronised with your connected coffee machine to make your coffee earlier than usual based on this information.

Connected objects therefore allow the automation of several actions according to different factors and in real time. Let's imagine what this could look like on a larger scale.

On a larger scale... In industry and production

The best example of what the Internet of Things can do for logistics is the container port of Qingdao in China. It is the largest cargo port in the world. Thanks to various sensors, connected objects and the arrival of 5G, which allows simultaneous connections and sufficient connection speed, the port has been fully automated. There are no longer any operators working directly on the site. Its automation has made it the fastest port to unload a cargo ship and its infrastructure can handle more than 30 containers per hour per crane. As the systems are automated, the port can also operate at night!On a city scale, the Internet of Things makes it possible, for example, to manage the network of traffic or streetlights. Indeed, thanks to various sensors, it is possible to automate this network. For example, when the light level starts to get too low, it is possible to switch on the city's streetlights. Similarly, traffic lights can be used to regulate and optimise traffic automatically according to the traffic information collected.

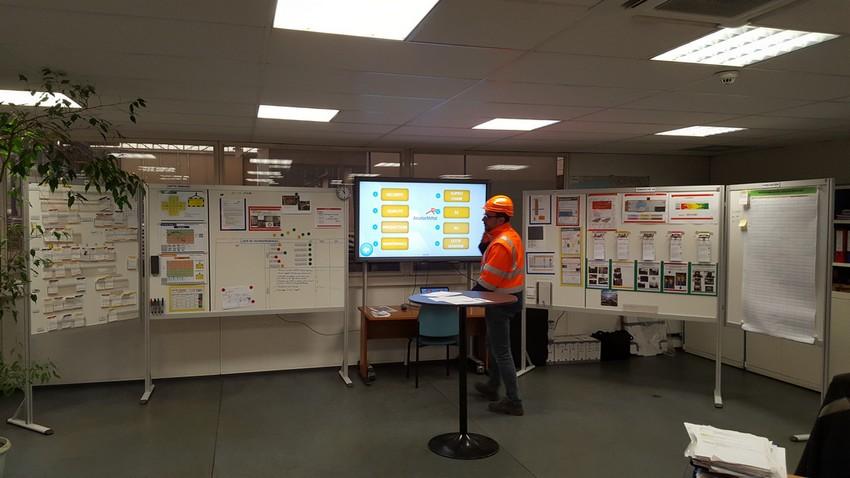

On a company scale, the Internet of Things can be used in production, for example, to supervise machinery equipment. Various indicators can also be followed to determine the company's performance. Software such as SESAHUB can be used to aggregate these indicators, set goals and provide real-time monitoring of all company departments on any connected screen. A simple glance at the software shows how the company is performing and where it is in comparison to the objectives set! This increases the motivation of employees who are working together towards a clear and defined common goal. In addition, it saves time in gathering of results in team meetings or weekly reviews! If you want to know more about Industry 4.0, you can visit our dedicated website sesa-systems-digital.com !

DOWNLOAD THE INDUSTRIE 4.0 CATALOGUE

Optimize your processes and improve your performance !

Discover all the concrete applications, tools to implement as well as our advice on our areas of expertise.

Need more information?

Do not hesitate to contact us if you would like more information or customized support.

Our experts are at your disposal.