In today's high-speed world, production facilities are under constant pressure to optimise their production processes and reduce waste. This is where the LEAN approach comes in. The Lean approach aims to identify and eliminate waste in all its forms through effective team management, thereby increasing efficiency, reducing costs, and improving overall quality. However, implementing the methods of this approach can be a daunting task, especially for those unfamiliar with the concept. Therefore, in this article we will look at how to measure and apply Lean methods in the factory. We will show how to identify waste, measure it and apply LEAN tools to eliminate it. By the end of this article, it will be clear how to transform your manufacturing processes from waste to continuous improvement!

Understanding the LEAN approach

LEAN is a methodology that aims to eliminate waste and optimise the production process. It is based on the Toyota production system, developed in the 1950s. The central idea of LEAN is to identify and eliminate waste in all its forms, including overproduction, waiting, transportation, processing, movement, inventory, defects, and unused talent. The goal of these methods is to create value for the customer and eliminate anything that does not add value.

LEAN methods are a continuous improvement process that involves everyone in the company, from senior management to workers. It requires a culture of continuous improvement, where everyone is encouraged to identify and eliminate waste in their work processes. It is not just a set of tools and techniques; it is a way of thinking that requires discipline, commitment, and perseverance.

What are the benefits of LEAN?

Firstly, LEAN reduces waste, resulting in cost savings, improved efficiency and quality of the product or service. This leads to increased customer satisfaction and loyalty.

It also has a positive effect on the moral development and commitment of employees. By involving the company's employees in the continuous improvement process, it creates a culture of empowerment and ownership. Employees feel valued and are more likely to commit to the organisation's goals.

Another benefit of LEAN is that it reduces delays. By eliminating waste and by simplifying the production process, LEAN reduces the time it takes to deliver a product or service to the customer. This allows for a better response to customer demand and increased competitiveness.

Measuring waste in the production process

To eliminate waste in manufacturing, it must first be identified and measured. There are several tools and techniques that can be used to measure waste, including:

Value chain mapping (Kanban)

Value chain mapping is a tool for identifying waste and unnecessary flows in the production process and determining where it can be reduced. It is a visual representation of the value chain that shows the material and information flows.

5S methods

The 5S is defined as a method of organising the workplace to eliminate waste and improve the workflow. We can divide them into 5 steps: eliminate, tidy, clean, standardise and respect. The purpose of these methods is to improve the performance of the company.

Kaizen

It is a continuous improvement process that involves all the people in the organisation. This structured approach is designed to improve the production process. The purpose is to identify and reduce waste and unnecessary flows in a systematic and sustainable way.

Apply LEAN methods in the workshop

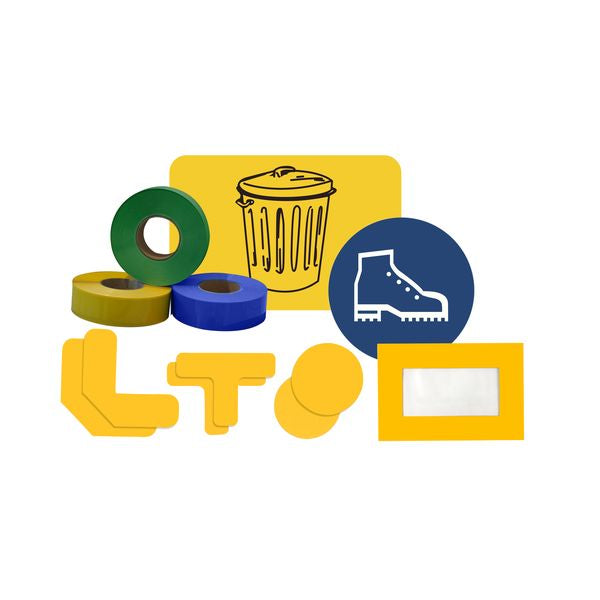

Several means and projects are available to apply LEAN methods in the workshop. We find products based on the 5s methods such as training games which aim to develop operations and raise awareness of the 5s methods throughout the company's teams. It is also a question of applying them on a smaller scale to guarantee their proper development. Ergonomic products implemented for workshop staff help to increase the quality of life at work and their involvement at work, as well as the company's performance and productivity. But also, several tools and techniques related to the LEAN approach can be used to eliminate waste from the production process. We find mainly:

Kanban

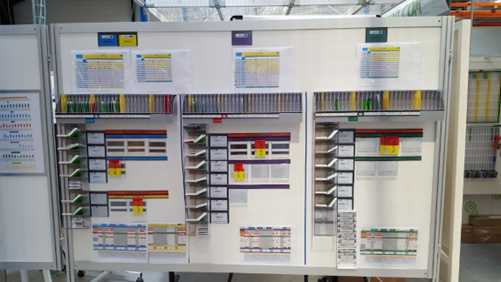

Kanban is a visual signalling system for managing stock levels and production flow. It ensures that the right parts are in the right place at the right time. It can also be used as an agile method in the organisation of production or any other work and project.

Poka-Yoke

Poka-Yoke is an error prevention technique that helps to avoid production errors. It consists of designing the production process and operations in such a way that errors are impossible or difficult to make.

Andon

Andon is a visual management tool for identifying problems in the production process. It involves using lights or signals to indicate that a problem needs to be solved.

Jidoka

Jidoka is a method of quality control which consists of stopping the production process when a problem is detected. It prevents the production of defective and unnecessary products.

What you need to remember

LEAN is a powerful methodology that can help workshops, factories, and production centres to improve their processes, reduce waste and increase efficiency and performance. By understanding the key elements of LEAN and applying the tools and methods, companies can transform their production processes and move towards continuous improvement and productivity. However, this requires commitment, discipline, and perseverance on the part of all company staff, the rewards are considerable.

SESA SYSTEMS supports you in the implementation of Lean methods with essential tools for their integration.