Explanation of the 5S method

Increasingly present in many organisations, the 5S method allows the optimisation of the environment, conditions and working time through the optimisation of processes and changes made to keep the workplace clean, tidy, and safe. Developed by the Toyota group, the Toyotism model is the ancestor of the 5S method, which is organised around 5 main steps.

The 5S method in 5 points

Seiri (Eliminate): The first step in 5S is to identify and then get rid of anything that is unnecessary and slows down the progress of the work. It is essential to know what is good to keep and what should be discarded.

Seiton (Ranger): The act of placing something in a strategic location to avoid wasting time looking for it and to access it as quickly and easily as possible.

→ Discover our storage foams, drawers as well as our 5S cabinets.

Seiso (Clean): Whether in the factory, in offices or in any other workplace, cleaning goes far beyond cleanliness through an organisation that gradually moves towards the principle of self-maintenance.

→ Discover our NETPOST cleaning stations as well as our MAINTPOST maintenance stations.

Seiketsu (Standardisation): The aim here is to respect the previous steps that have been put in place and to stick to them in the best possible way. Visual management is recommended to avoid any deviation.

→ Find out more about our PRODOC, our display panels, our MULTIDOC and our floor marking.

Shitsuke (Respect): Adhering and maintaining are the watchwords of this step. The 5S method must become a habit for all staff.

→ Discover SESA CHECK as well as our anomaly reports forms.

The essential tools for implementing a 5S method

Initially developed in production workshops, the 5S method has gradually spread to company offices and professional environments. The implementation of the 5S method takes place in several ways in companies that have decided to adopt it.

Ergonomic products

Ergonomics at work is the consideration of the well-being of workers, which consequently improves the quality of work as well as productivity. This involves improving the work environment and the tools used, which will have an impact on physiological, psychological, and social aspects. This is an important issue for companies because of its impact on musculoskeletal disorders (MSD). Innovative ergonomic products are designed to reduce these risks and increase the well-being of everyone at work. We can distinguish 2 types of work environment:

- Work in workshops, factories, and production centres: the aim is to limit and reduce physical pain for workers as much as possible. To limit these pains, with a multitude of accessories at disposal, we propose anti-fatigue mats, modular workstations, ergonomic stools as well as electric workstations.

- Office work: The aim is to relieve workers of pain caused by static postures and to eliminate bad postures. Products such as height-adjustable swivel chairs and electric desks improve the working comfort of employees.

→ Discover our accessories in our office range.

Clean-up point

The idea is to put in place, in the spaces where it is necessary, essential cleanliness points to meet the 5S method's requirements. SESA SYSTEMS offers you a number of variations adapted to each work environment and its requirements.

The Clean Point station provides an instant view of the cleaning tools needed in the given area through the printed patterns on the panel and saves the time spent searching for or replacing items that go with it. The management of reduced spaces in an organisation contributes to the application of sustainable development as well as to cleaning. That's why we offer wall-mounted cleaning stations for sale, which are mounted on a vertical wall and show the full range of cleaning tools available. If mobility is required, your cleaning station can be mobile and allows for ergonomic use of the tools required for maintenance work thanks to the swivel castors fixed with brakes.

Display cabinet

This new concept of workshop storage cabinet is based on the 5S method with its doors with transparent PMMA fronts, there is no need to open the cabinet to see the contents inside. The storage inside the visual cabinet is optimised through the Lean Manufacturing strategy, a strategy that aims to get rid of unnecessary operations and to have a better management of the stock items, and a better maintenance of the storage.

Aerial signage

Whether it's in office spaces or workshop production areas, it is important to indicate the arrangements of each section in a company to create "visual factories". The aerial banners offered by SESA SYSTEMS are fully customisable with the possibility of entering your own text in addition to the choice of the width of the banner and its fixing.

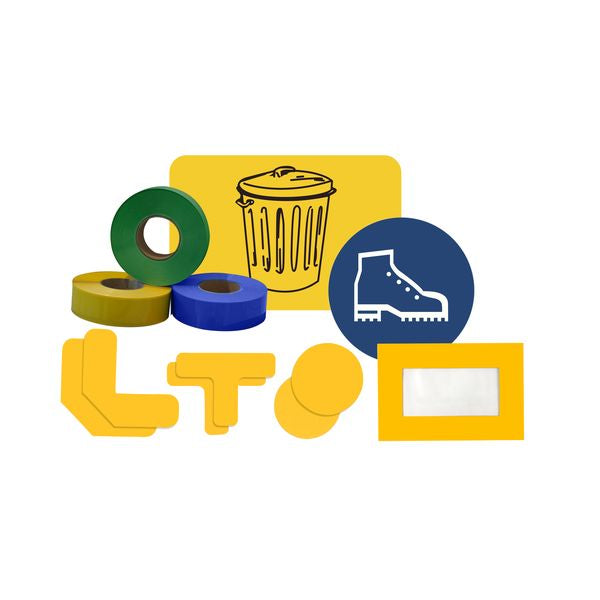

Floor signage

As part of an approach to improving safety and optimising production workshops, floor signage makes it possible to delimit dangerous accesses, zones, and passages. This type of Visual Management will guarantee the prevention and reduction of risks within your workshop. All of this is part of the LEAN Management dynamic, which aims to optimise the operation of a warehouse using certain methods. Floor marking is ideal for marking protected areas, marking footpaths, and indicating storage areas for safety equipment. Our adhesive pictograms for floor markings can be used to inform and alert workers on risks present in certain areas of the production floor.

Training games

With the aim of integrating and involving all staff in the adoption of the 5S method, our 5S training game enables training and discovery of the particularities of the 5S method. The aim is to train staff in the 5S method in a fun and interactive way before implementing these new methods in the field.

What to remember

The 5S method can be a game-changer for any business looking to improve productivity and safety in its premises. The five principles of 5S enable companies to create a lean and efficient workspace for employees that work smarter, not harder. By continually improving the 5S method, companies can ensure that they are always working at maximum efficiency and achieving their goals while keeping their people safe. Want to learn more about 5S and its application in business? Discover our free 5S guide now.