Workshop furniture

SESA SYSTEMS applies LEAN Manufacturing principles with your workshop furniture. A neat and organized industrial workspace adds value to operators’ work. It helps their efficiencies and reduces the risk of injuries and accidents. Ergonomics in industrial workstations is a powerful way to prevent MSD (Musculoskeletal Disorders) and improves operators’ working conditions.

However, creating the perfect workshop environment requires thoughtful consideration of workshop furniture. A modular system that maximizes space and promotes efficient organization is the ideal solution for any team. The inclusion of versatile units, such as cupboards, cabinet and lifts, ensures that tools and equipment can be stored and accessed seamlessly. With a high level of customization available, the modular workshop furniture allows for the creation of a tailored space that meets the unique needs of the team with carefully placed cupboard, cabinet and furniture.

SESA SYSTEMS, a highly regarded manufacturer in LEAN and ergonomic work environments.

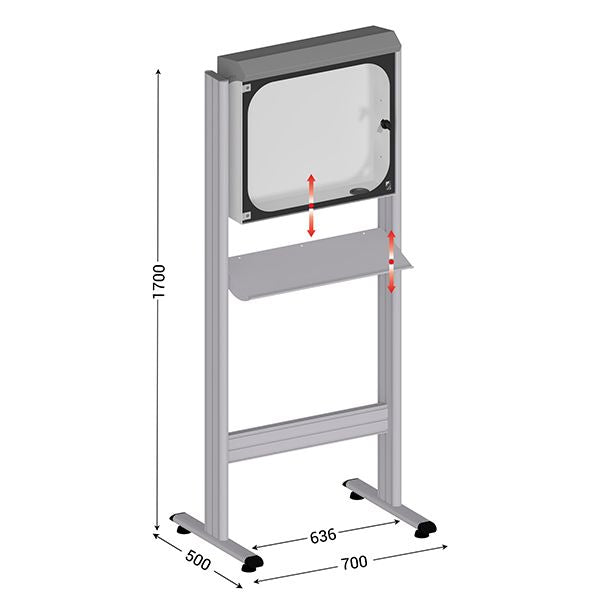

SESA SYSTEMS has been highly recognized for its workstations since 1990. In the industrial field, the operators' work organization is crucial for productivity. Thanks to a range of flexible and customizable professional furniture, each work configuration can be specifically optimized. As such, the shelve measurement is made to fit your specific workstation. By the same token, some industries such as food, selected laboratories or chemical companies are subject to sanitary standards and can not use laminated shelves. Our range STAINLESS STEEL addresses this issue. The use of different materials, compartments, boxes, drawers and industry related equipments increases storage needs. Having this type of choices is made possible because the assembling structure is made of aluminium. In heavy industrial environments - where equipment is subject to dust fall or liquid spill - computer workstations and PC furniture enclosures ensure your equipment protection. quality control stations integrated ergonomics functions and 5S methodologies.

Ergonomics is at the core of our workshops to fight drudgery and increase comfort.

MSD is a common disease for operators working on factory floors or making physical and repetitive tasks at work. To prevent MSD development, our ergonomic collection includes anti-fatigue mats, sit-stand seats or adjustable workstations with perforated bottoms to hang tools and avoid needless movements. For jobs requiring precision and good lighting, some stations have adjustable lamps and lighting. Thanks to this collection, operators feel less tired, limit useless gestures and are therefore more productive.

Effectively organizing your workshop furniture (cabinet and cupboard for example) is crucial in preventing MSD. Start by designing a layout that maximizes space and strategically places workbenches, cabinets, and cupboards to create an ergonomic and efficient workspace. Utilize modular storage solutions to keep a range of tools easily accessible and properly stowed away, reducing the need for unnecessary movements. Invest in adjustable chairs and anti-fatigue mats to enhance worker well-being during extended periods of equipment use. Regularly declutter the workshop to eliminate tripping hazards and create a safer environment. Training employees on proper lifting techniques is a necessary solution, and having designated spaces for specific equipment within the garage or workshop ensures a streamlined workflow. This comprehensive approach to organizing furniture and equipment not only addresses the immediate need for a well-structured workspace but also contributes to preventing MSD and promoting a safer, more productive work environment.

5S concept application for a controlled industrial environment.

The 5S method is crucial in workshop furniture organization as it provides a systematic approach to enhance efficiency, productivity, and safety in the workspace. The principles of Sort, Set in order, Shine, Standardize, and Sustain help create an organized and clutter-free environment. In the context of workshop furniture, implementing 5S is a solution that ensures that tools, equipment, and materials are sorted and organized, reducing unnecessary clutter and promoting a more streamlined workflow. This helps make your services more efficient and provides a high quality work for your customers.

Poorly organized workspaces waste time. A messy work environment is counterproductive and may even diminish operators’ motivation. The 5S method reduces time-waste by organizing workspaces and assigning a specific location for each tool. Thanks to this method, everything is well organized and located at the right spot. Several SESA SYSTEMS products help to apply this method, including our 5S cleaning stations and workshop storage cabinets. They come with a variety of accessories and can be customized to your needs.