Does it take your employees 5 minutes to find a document on their desk or a tool in their workspace? Does such a cluttered and overloaded environment discourage them from working or committing to achieving their goals? Improve your work environment by adopting the 5S method, which will solve all these organizational problems within your departments, offices, and workshops.

Definition of the 5S management technique

The 5S method is a practice for optimizing working conditions and the working environment, as well as working hours, by ensuring that the environment remains tidy, clean, and safe, and by establishing rigor. 5S is a work system that's easy and quick to implement. Of Japanese origin, it consists of 5 steps. Several meanings can be associated. It all depends on your activity, as 5S was designed for workshops and factories, but can easily be adapted to departments, offices, or even your home! Here are the 5Ss of the 5S method of Lean Management in detail.

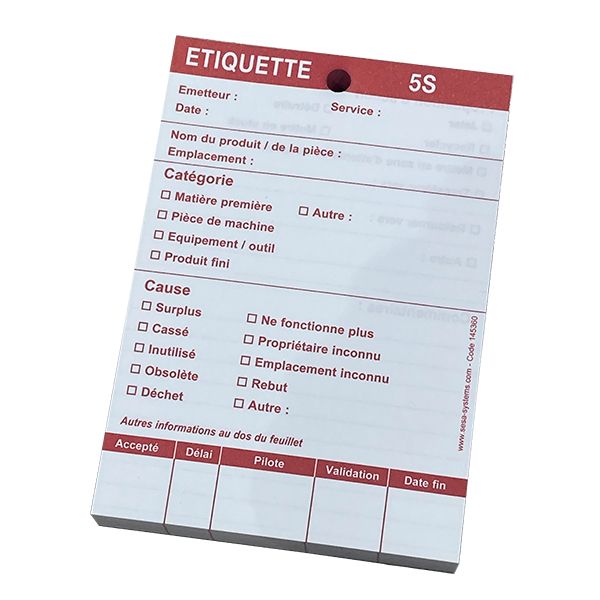

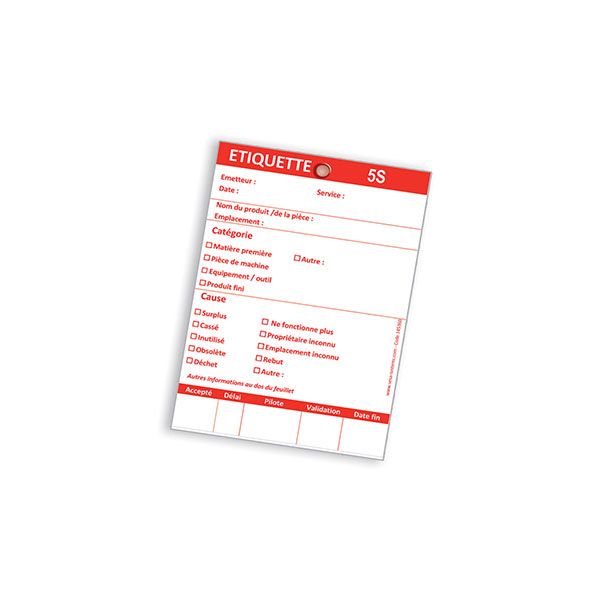

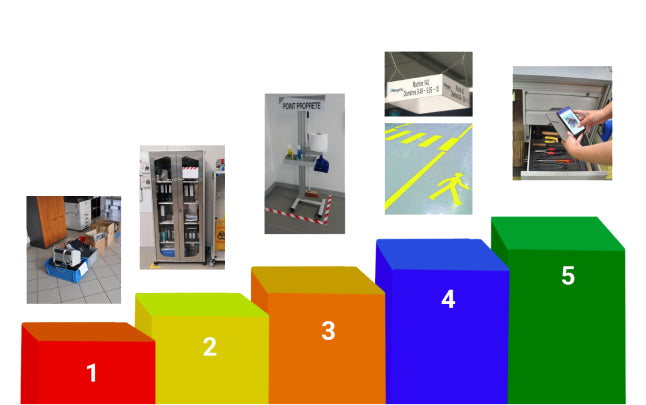

1st S: SEIRI

ELIMINATE, Elimination is the first priority in 5S: Start by getting rid of everything that is not absolutely necessary. It’s important to keep what’s important, but it’s just as important to get rid of what isn’t. And what matters above all is knowing what to keep or not.

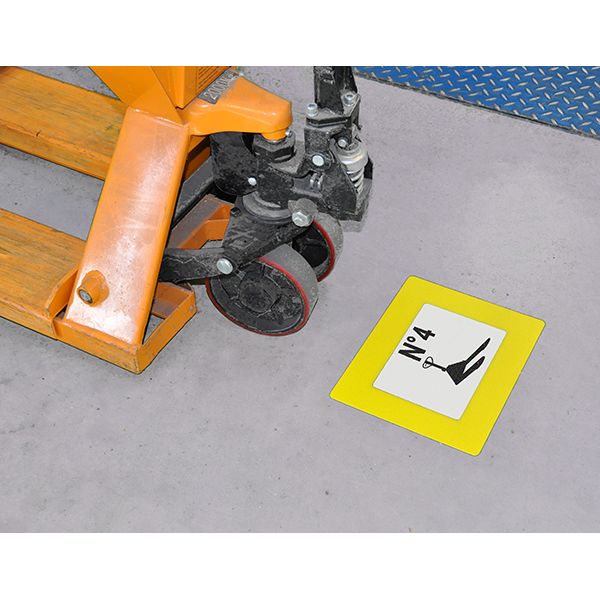

2nd S : SEITON

SET IN ORDER, Tidying up means putting things in specific places so they can be found straight away when needed, thus avoiding wasted time searching.

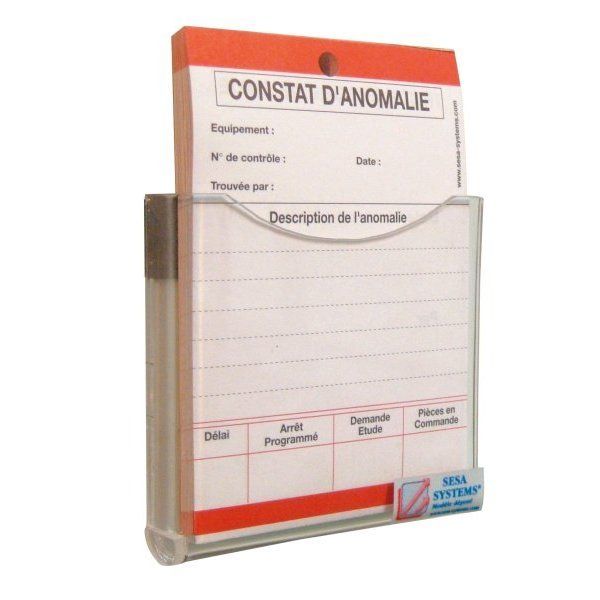

3rd S : SEISO

SHINE (or CLEAN), Cleaning offices, work places, and production tools is not just cleaning for the sake of cleanliness. In some cases; such as machines and tools, it's a first step towards preventive maintenance. It's often during cleaning that anomalies and premature wear are detected.

4th S : SEIKETSU

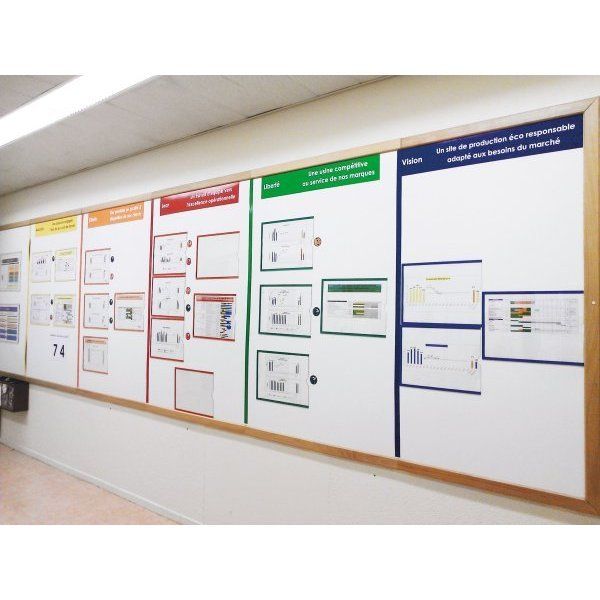

STANDARDISE, This stage defines rules by which the workplace will remain free of unnecessary objects, tidy, and cleaned. To eliminate the risk of disorder, Takashi Osada advocates Visual Management that relies on a number of aids.

5th S : SHITSUKE

SUSTAIN, Newly established rules must be obeyed, and therefore staff must be encouraged to stick to them. It’s a simple case of routinely doing what needs to be done, so that 5S does indeed become a matter of routine.

Method created by the TPS, Toyota Production System

The 5S method has been developed by the Toyota group in the Toyota Production System context. The 5S approach aims to improve the employee's working environment, but it is not the only Lean method created by Toyota. Inspired by Fordism, Toyotism has proven to be efficient and has been further developed to create the 5S. This remodelled technique has proven itself over time. It is a company management tool aiming at:

- Minimizing wasted time and energy

- Checking the quality of products on the production line

- Producing according to the Kanban method in order to avoid overproduction or underproduction

- Listening to operators to facilitate communication.

The objectives of the 5S method

Progress is possible when everybody makes a commitment. This collective commitment starts by taking into account each person’s work environment (machine, line, laboratory, office, store, etc.).

More than just a simple technique for keeping order, 5S is first and foremost a participative management method that gets employees involved in improving the organization of a workplace. This action calls for participation at every level of the hierarchy.

All five parts of 5S are vital when embarking on a continuous improvement initiative. They help share the necessary mindset for continual improvement.

The 5S method is based on the observation that a clean and tidy workspace is conducive to good production quality.

Benefits of the 5S method

Direct results

- Cleanliness and tidiness at the workstations and their surroundings

- Implementation of visual organization

- Elimination of wasted time and materials

- Improved flow management

- Decreased risk of work accidents

- Better working conditions

- General improvement in the environment

- Better site image for visitors

- Improvement of equipment control

Benefits in terms of behavior

- Communicating and leading a team based on well-defined topics (the five “S”)

- Establishing standards (rules)

- Capitalizing knowledge and know-how as assets

- Respect commitments and collective rules (“saying what you do and doing what you say”)

- Re-examining habits

- Coming forth with initiatives and creative solutions

- Delegating certain activities to internal stakeholders

- Make acquired results longlasting and ensure ongoing progress

- Improved workflow

Workstation with 5S

The 5S method enhances the image of your workstations, workbenches, cells, sectors, production workshops and offers:

- A new aesthetic with flexible aluminum structure

- Increased productivity and efficiency

- Decreased accidents, outages or technical malfunctions

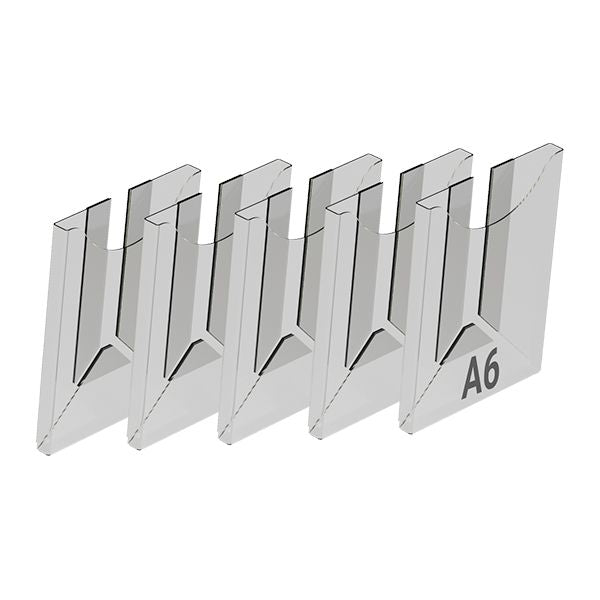

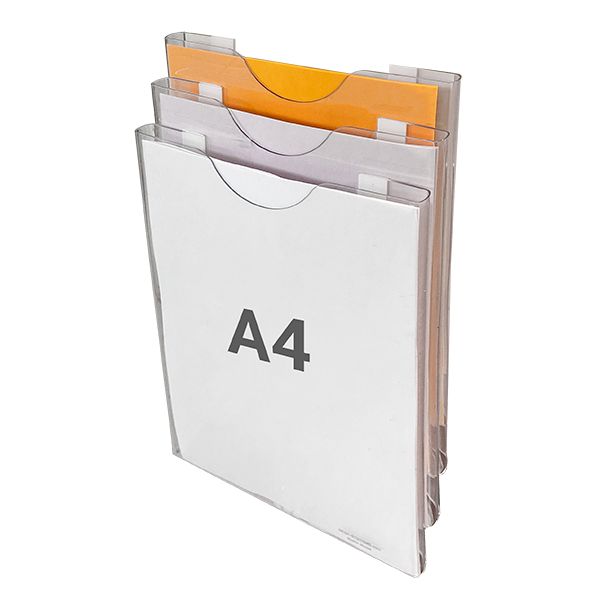

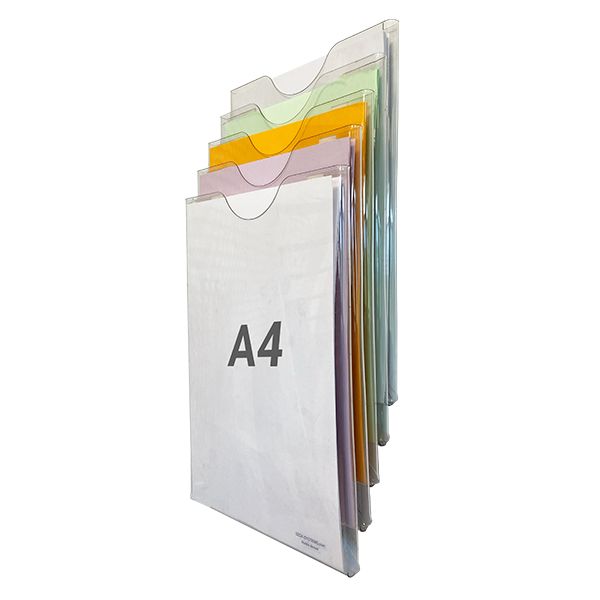

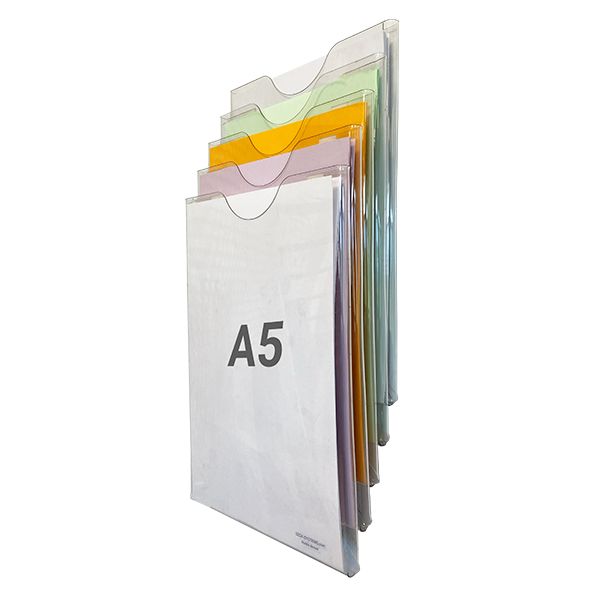

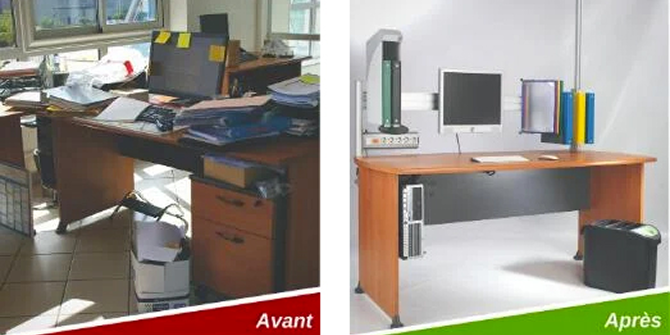

Office with 5S

The LEAN Office is a management technique that offers a complete solution within the company, services, offices such as:

- A better organization and increased quality of work

- Effective visual presentation

- Decreases the time in locating a document, or reduces problems if the operator is not present

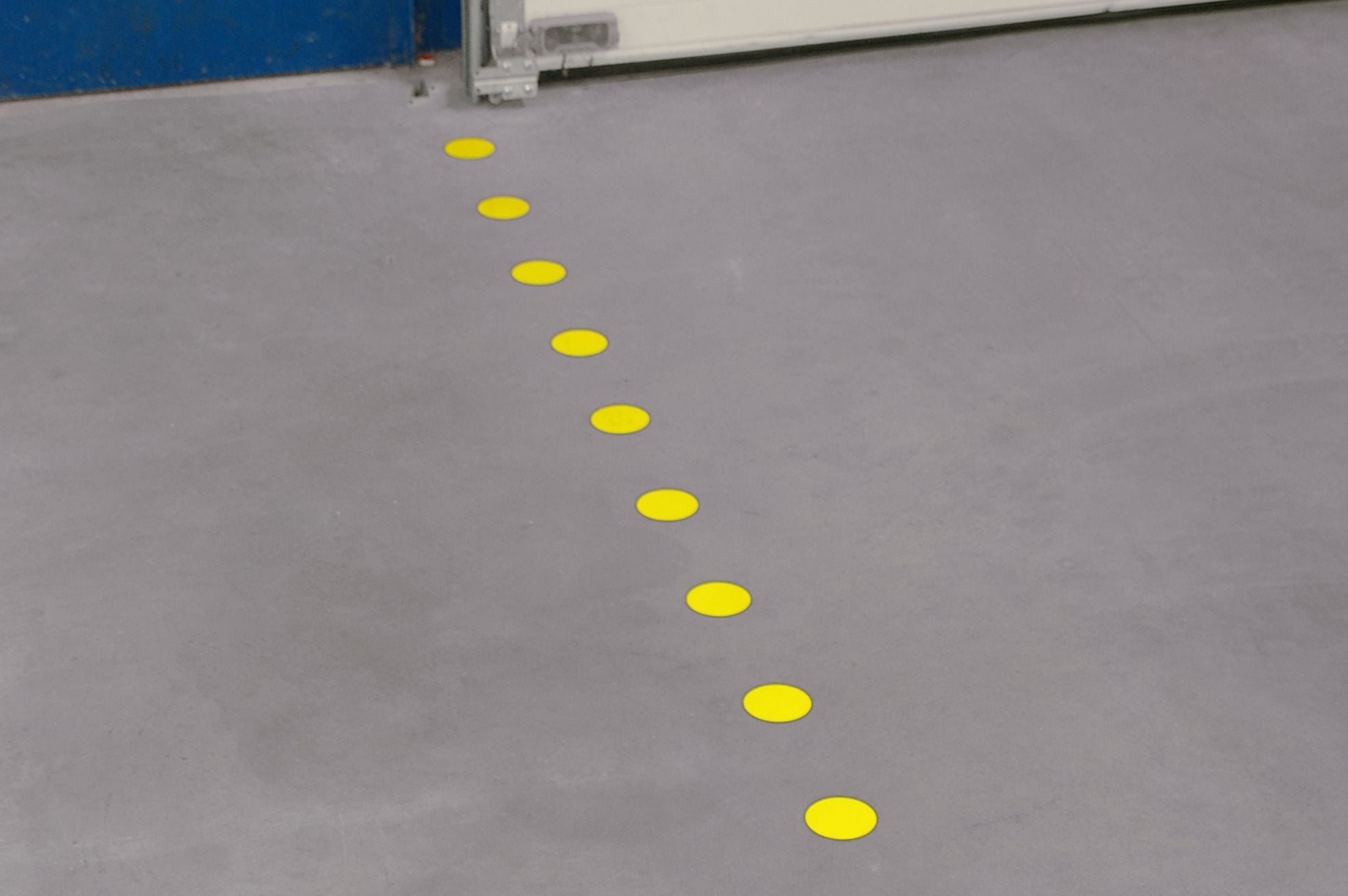

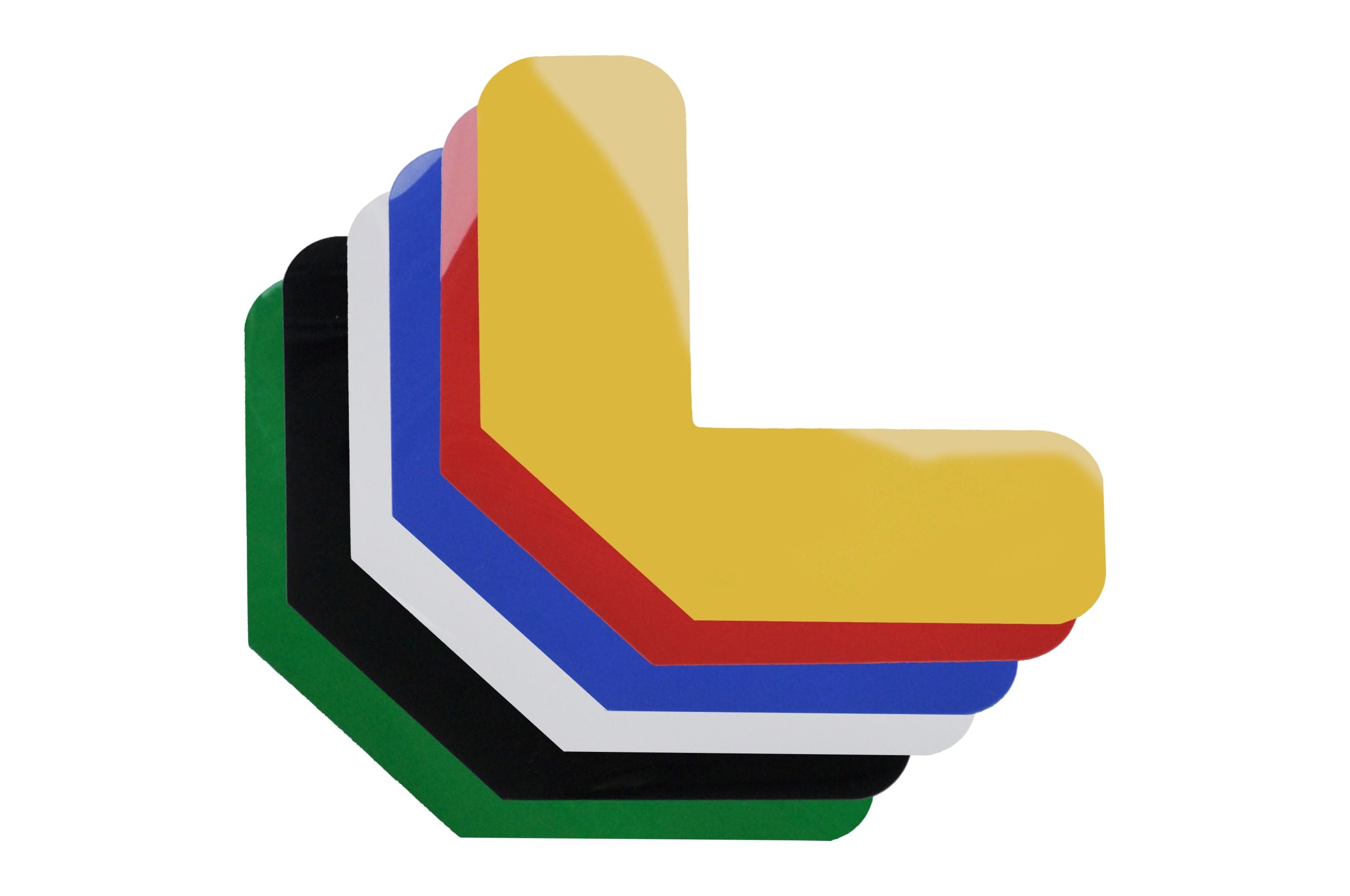

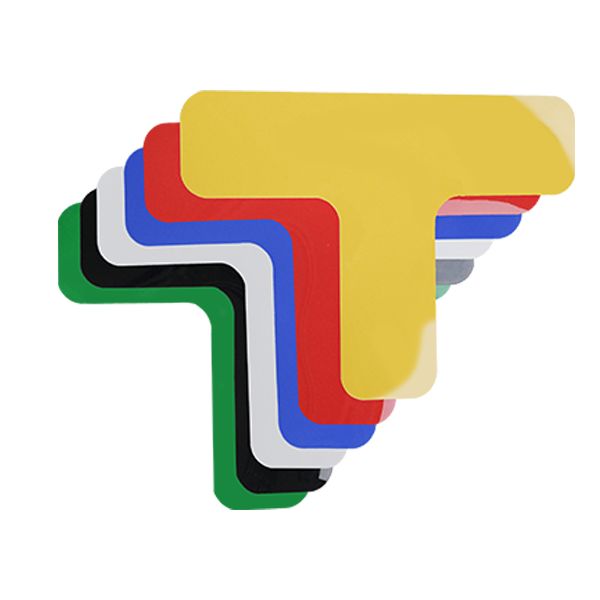

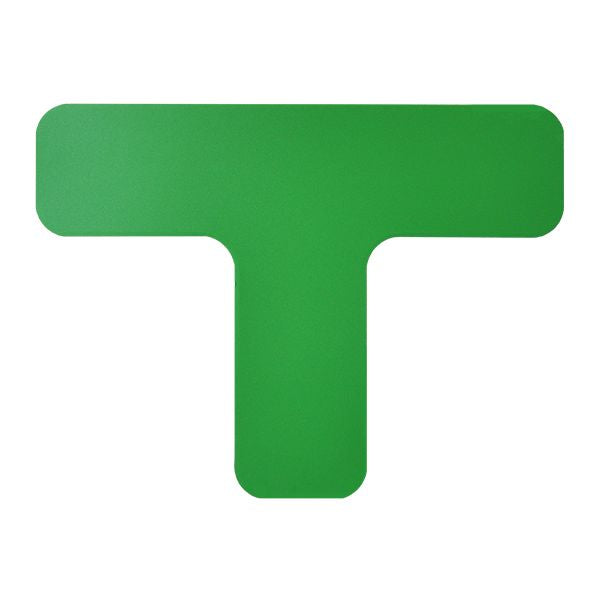

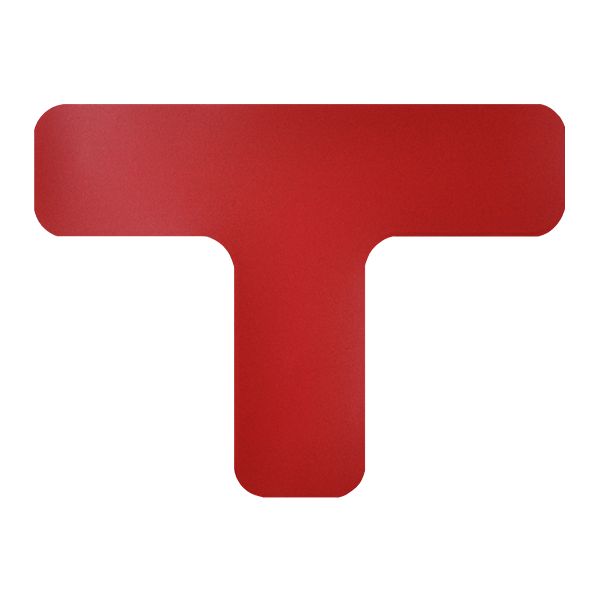

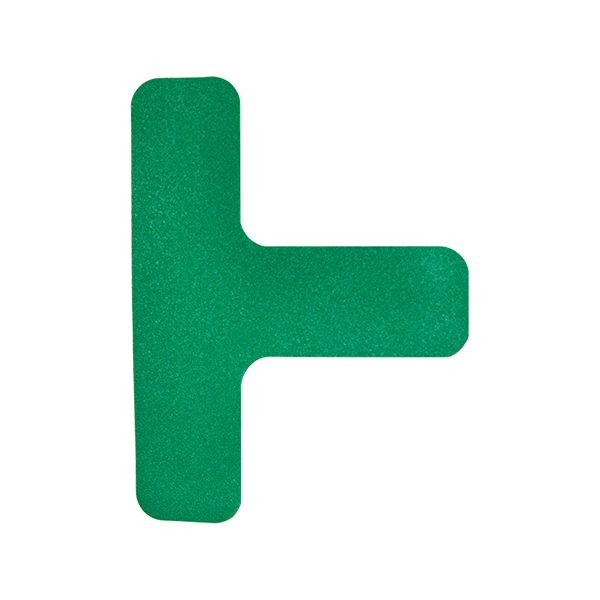

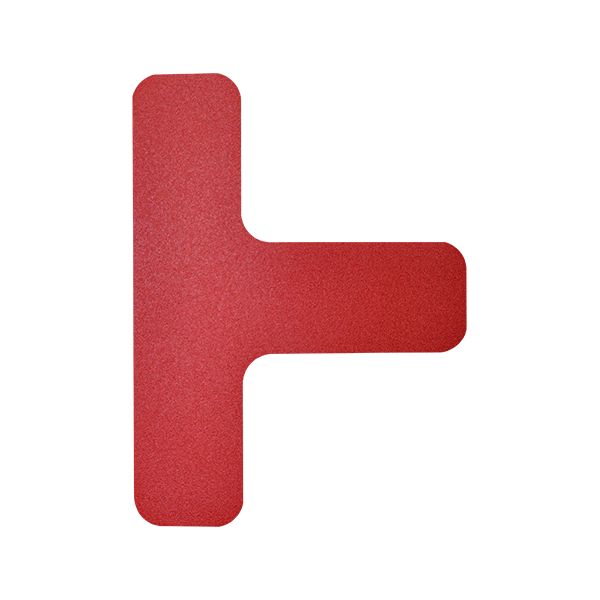

Signage using the 5S

For a clean, organized and functional environment, using 5S signage provides the following benefits:

- Ergonomic operations, with clean tools

- A predefined cleaning process

- Well organized work items

Succeeding in your 5S implementation

The 5S approach is participative. You must ask production operators to revisit their work in terms of efficiency, based on their experience, everyday constraints, and any ideas for improvement that they might put forward and implement. This roll-out method is especially motivating because it gets participants immersed and involved.

Implementing 5S is also an opportunity to enrich operators’ jobs by delegating to them the routine servicing of machines and equipment. It may be necessary to provide initial training by maintenance experts, who can work with your operators to develop the appropriate operating procedures. For many operators, this experience is enriching and very positive. It elevates their job to more than fetching, carrying, and twiddling knobs and involves them more on a day-to-day basis.

5S method training through games

Learning by playing team games is a more effective and sustainable way to learn and create new habits. It enhances everyone’s work experience by providing rich, original and rewarding learning situations. Team members who play a 5S training game gain a personal experience that increases their awareness of the need for 5S. They will also understand how to put it into practice and how to apply it to their everyday work.

Average duration: 2h to 3h

Participants discover the importance and principles of 5S by reconstructing scenarios with images that represent the five steps of 5S on a board game.

Number of participants: the ideal number per game is 10 people: operators, technicians, team leaders, heads of workshop, executives, etc…

To go further

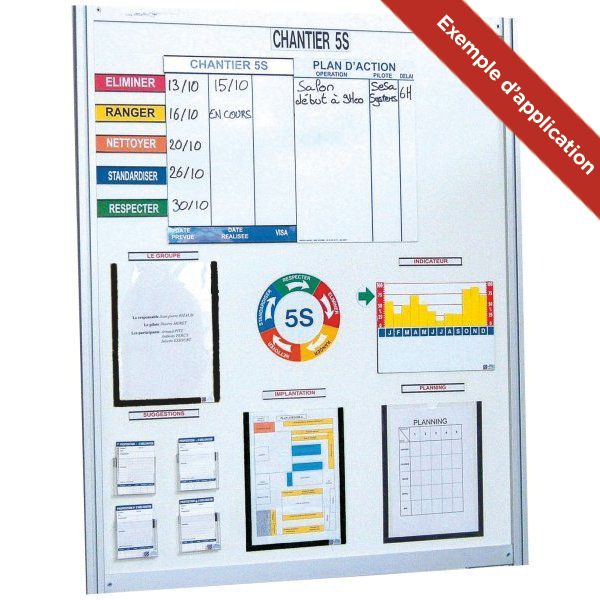

5S Method Starter Kit: Fast and efficient construction of various LEAN projects such as: 5S, HOSHIN, KAIZEN, SMED, LEAN, Dashboard of autonomous teams as part of the PILOTE project as a result of the game.

Results: collective, shared and effective success.

You can find the other LEAN methods: 5S, Kaizen, Six Sigma, LEAN Office, LEAN Manufacturing, TPM, OEE, Machine Day, Visual Management.