Industrie 5.0

Discover our website dedicated to Industry 5.0

Industry 5.0 represents the fifth industrial revolution and follows Industry 4.0. Its core principle is to enhance cooperation between digital technologies, internet connectivity, and humans in industry, emphasizing adaptability, creativity, and flexibility. There is an idea of immediacy and information sharing at all levels of the company — it is a component of the IoT (Internet of Things). Many see the adoption of these new technologies as the factory of the future, the smart factory that will initiate a transformation enabling optimized decision-making through constant access to information. In this sense, data and its use are at the heart of this system. Indeed, from management to manufacturing and automation, machines can take advantage of this data to, for example, increase productivity or reduce costs, ensuring the best lead time and price for the customer. Artificial intelligence and cloud processing can also serve Industry 5.0 by anticipating customer demand levels and producing intelligently as a result.

IOT, an actual digital company revolution

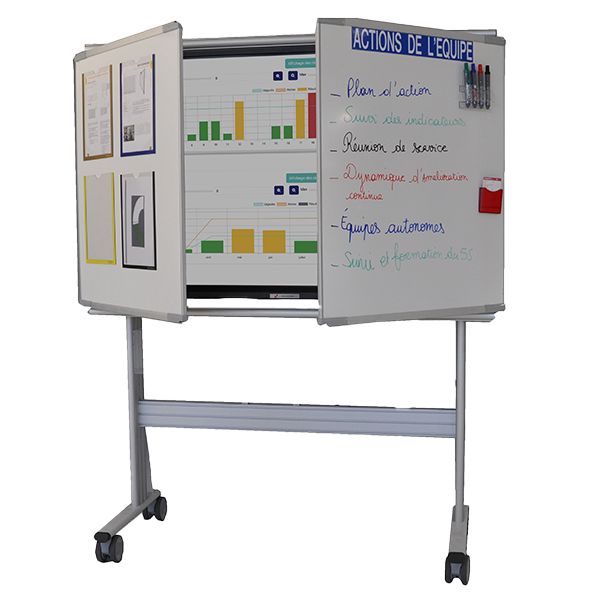

SESA SYSTEMS, a major player in the development of LEAN Manufacturing and LEAN Management, is developing a new series, Digital Visual Management. This managerial solution facilitates information sharing and enables managers to communicate their goals more easily. This essential LEAN technique relies on multiple communication techniques. Digital tools apply the same LEAN principles and take them to the digital world through the use of Internet and connected screens. They enable operators to immediately adapt to new information and apply the right processes accordingly.

Ubiquitous and always available information thanks to the connected screens technology

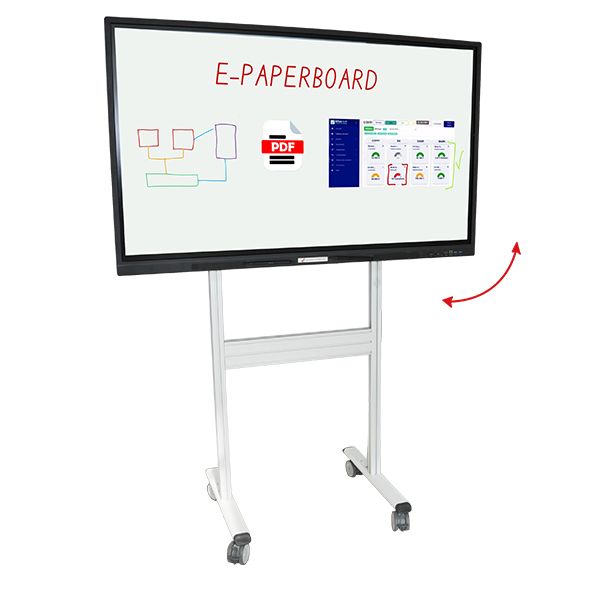

Thanks to connected objects and other smart-devices, screens become the prevailing information source and transmission device. E-LEANBOARD connected screens can display real-time performance indicators. Interactive touch-screens enable team members to easily annotate or comment information. E-MEETING INTERACTIVE TOUCH is an actual interactive screen which enables users to use their fingers or stylus to interact with the screen’s content.

These devices provide interactive animations that can be customized for team meetings. Whatever appears on the interactive screen can be modified or reworked at any time by team members. SESA SYSTEMS is presently developing digital visual management solutions for computer applications. Used on the network, these connected elements can be used in production sites and offices.

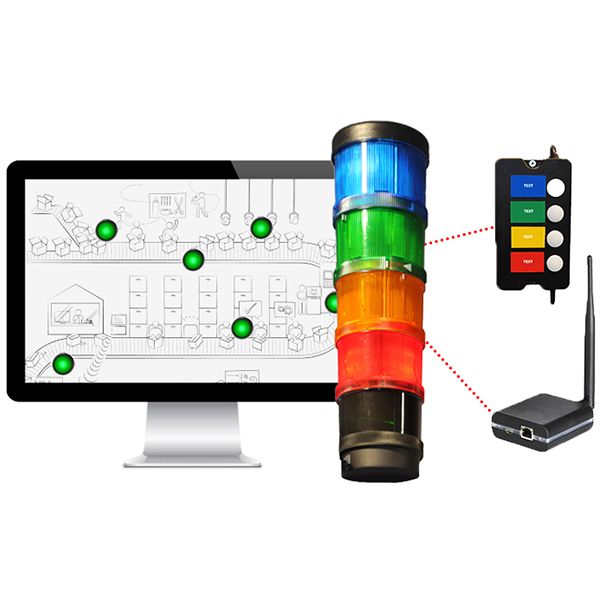

Effective visual indicators for optimal organization

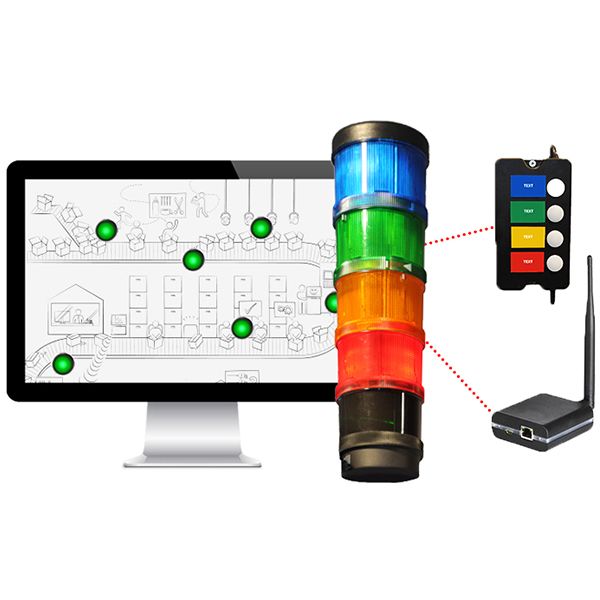

SESA SYSTEMS offers a range of innovative products. ANDON light column can be installed at operator’s workstations to provide compelling visual or sound information. These indicators help detect and identify origins of cycle issues in the production cycle. Several colors are available. Thanks to their radio modules, LEANANDON columns offer great flexibility.

Discover SESA SYSTEMS products and successfully transition into the new industrial era by delivering real-time quality information within your organization.