300 novelties

to fully satisfy you

LEAN tools and approaches

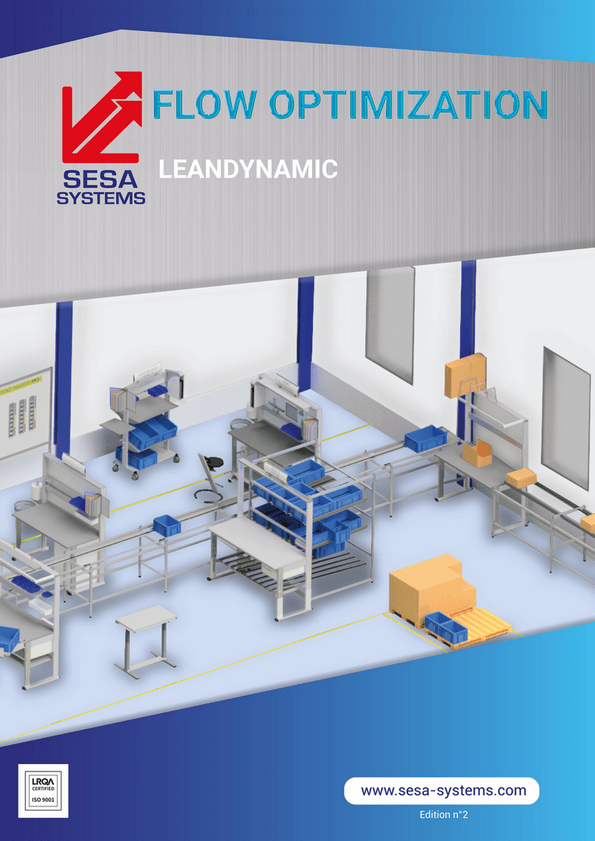

In times of crisis, to remain competitive, companies need to adapt their activities rapidly to a tense environment, without systematically resorting to investment. Originally developed by Toyota, Lean links performance (productivity, quality) to the flexibility of a company, which must be capable of constantly reconfiguring all its processes (industrial responsiveness). Lean proponents seek performance through continuous improvement and continuous improvement through the elimination of waste (MUDA).

Among the main improvement activities, this strategy shows the effectiveness of flow analysis, pull production and the anchoring of Kanban, operational performance measurement, quality production, constant reduction of the 7 types of waste, visual management, order and cleanliness (5S) and the reduction of changeover times (SMED).

Here are the main benefits of flow optimization:

Increased process quality means fewer errors, rework and rejects. This means less use of company resources, and therefore lower total operating costs.

Our guides focus on Lean, Industry 4.0 or ergonomics. Download them for free now.

Discover all our catalogs