Why and how to develop KANBAN in companies with the LEANFLASH range?

KANBAN, a pillar of Lean Manufacturing, is much more than just a visual task management system. It embodies operational efficiency and the fluidity of processes in companies. Proper integration of the LEANFLASH batch boxes and batch launchers into KANBAN is a key strategy to further optimize workflows and minimize waste.

What is KANBAN?

The KANBAN system has its roots in the "just-in-time" philosophy of the Toyota Production System. It is based on visual maps used to indicate production needs. These cards act as signals to regulate workflow, optimize inventory, and reduce lead times. The essence of KANBAN lies in its ability to synchronize production with actual demand, thus avoiding overproduction and bottlenecks. Producing efficiently in this way helps avoid waste due to overproduction as well as delivery delays due to demand being too high in relation to production. The elimination of these MUDAs is one of the goals of LEAN Manufacturing.

LEANFLASH batch boxes and batch launchers, what are we talking about?

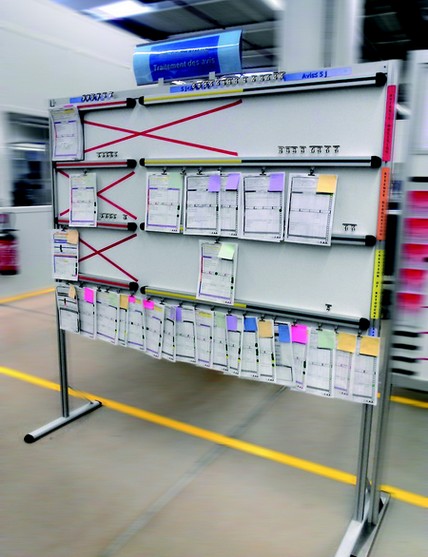

LEANFLASH batch boxes, an essential component of the KANBAN system, control the amount of work in progress. They visually delineate the acceptable thresholds for each step of the process, thus preventing overwork. By limiting production quantities to what is needed, they help reduce excess inventory, improving the overall efficiency of the system. LEANFLASH batch launchers, on the other hand, act as triggers in the KANBAN system. They initiate production or move a work batch to the next stage when batch boxes reach a certain critical level. This approach helps optimize workflows by avoiding unnecessary downtime, while maintaining a balance between demand and production capacity.

How to integrate LEANFLASH Kanban tools such as batch boxes or batch launchers in companies?

Successful integration of batch boxes and batch launchers into the KANBAN system requires an approach tailored to every type of business. Applications and needs vary depending on the nature of the business and its business processes. In production industries, the use of batch boxes and batch launchers can focus on the management of production lines. Batch boxes can be used to control the inventory of parts or semi-finished products at each stage of the production line. Batch launchers can then trigger the manufacture or transport of new batches as soon as critical levels are reached, minimizing downtime and optimizing production. For service companies, the integration of batch boxes and batch launchers is a bit different and can result in project management. Batch boxes can represent the different phases of a project, and batch launchers can signal the need to deploy additional resources or move on to the next phase after a step is completed. This helps to maintain smooth project progress while avoiding unnecessary delays. It should be noted, however, that this integration is often computerized via KANBAN management tools. The purpose remains the same, however. In logistics or distribution companies, the use of batch boxes and batch launchers can focus on inventory and order management. Batch boxes can delineate the quantities of products to be stored at each location, while batch starters can signal replenishment as soon as inventory reaches a set level, ensuring consistent product availability without excessive overstocking.

What you need to remember

Regardless of the industry, careful assessment of the specific needs of the company is essential to developing KANBAN. The harmonious combination of batch boxes and batch launchers with the KANBAN system represents a significant step towards the continuous improvement of operational processes. Indeed, these tools offer increased visibility, more accurate inventory management and a significant reduction in waiting times. In practice, this translates into better management of production, stocks or time, which makes it possible to generate significant financial gains and better customer satisfaction. By adopting these practices, companies can increase efficiency while maintaining a high level of quality and responsiveness to market demands. In order to get your Kanban project off to a good start, you can opt for the KANBAN training game which will train and raise staff awareness of the challenges and principles of this method. In addition, you can contact our account managers who will advise you on the implementation of this system within your premises.