As businesses grow, their production also increases. If processes, facilities, and organisation don't keep pace, this can lead to disorganised workflows, missed deadlines and reduced productivity. Fortunately, there is a solution that can help streamline production processes and improve efficiency: the KANBAN planning method.

KANBAN is a Japanese term meaning "visual signal" or "map". It is a production planning system that helps companies manage their workflow by visualising tasks and limiting work in progress, in other words, making organisation more fluid.

By using Kanban boards and cards, teams can easily track the progress of tasks, identify potential problem areas, and prioritise work.

In this article, we take a closer look at Kanban planning and how it can transform your production strategy and help you optimise your workflows.

What is KANBAN planning and how does it work?

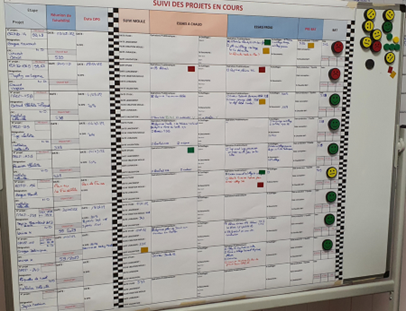

KANBAN planning is a visual planning system that helps teams manage and optimise their workflows, production, inventory and planning. These management methods were originally developed by Toyota in the 1950s to improve its manufacturing processes. The system was based on the idea of 'just-in-time' production, meaning that parts were only produced when they were needed for the manufacturing process. KANBAN planning works using a KANBAN board, which is essentially a visual representation of your workflow.

The board is divided into columns that represent the different stages of your production process, such as "To Do", "In Progress" and "Completed". Each task or project is represented by a card that moves around the table as it moves through the various stages of the workflow. The aim is to limit the number of cards in progress, enabling more agile stock management and ensuring that work flows smoothly.

KANBAN planning is based on the 'pull' principle, where production is pulled from downstream (customer) to upstream supplier. This means that it is customer orders that trigger the manufacture of parts, by sending orders back upstream from product output.

This avoids overloading team members and ensures that tasks are completed on time. By limiting work in progress and visualising tasks, teams can prioritise their work and focus on the tasks that are most important to the business.

The benefits of KANBAN planning

The main advantage of the KANBAN method is that it avoids overproduction and its consequences. Raw materials, components and sub-assemblies will only be delivered if there is a demand for production. This makes it easier to prioritise work and ensure that tasks are completed on time.

KANBAN planning also helps to avoid overwhelming team members by limiting the amount of work in progress at any one time. This prevents burnout and ensures that tasks are completed in the right conditions.

The KANBAN method promotes continuous improvement by enabling teams to identify and map their workflows, and their potential for optimisation and improvement.

With the aim of increasing stock rotation and reducing the risk of goods being lost and your company's overstocking costs, the FIFO (First In, First Out) method, which is part of KANBAN planning, enables stocks to be managed by removing items acquired first.

In practical terms, this means using older goods before newer goods. You can use LEANFLASH FIFOFILE magnetic and FIFO file organisers as KANBAN planning solutions.

Another advantage of KANBAN scheduling is that it is highly flexible and can be used in a wide variety of sectors and contexts. Whether you're managing a software development team or a manufacturing plant, KANBAN scheduling can help you optimise your workflows and achieve greater success.

Compared with traditional planning methods, the KANBAN method offers a number of advantages: it is a visual tool that everyone can understand, it reduces lead times at every step, and it is a cost-effective method that requires no major investment.

The KANBAN method is also a sub-category of the "Agile" project management model, which is based on progressive development, flexible planning, the shortest possible deadlines, and continuous improvement. The scrum approach is also a methodology that is similar to the Kanban methods, since it is dedicated to project management and aims to improve team productivity and product optimisation.

The KANBAN method implementation

Implementing KANBAN planning in your company is relatively simple. The first step is to create a KANBAN board that represents your workflow.

Our physical display boards enable Kanban planning to be carried out in your company and are available for sale on our website.

For example, in this image, each column can represent a stage in your production process.

The next step is to fill the KANBAN board that has been set up with tasks or projects. Each task can be represented by a card that moves across the board as it progresses through the workflow.

Finally, it's important to regularly review your KANBAN board and make any necessary changes. This will optimise the workflow and ensure that tasks are completed on time. Immediately, you can see where you stand.

Find out more about our KANBAN cards:

→ customisable colour KANBAN cards

→ transparent magnetic KANBAN cards

→ transparent KANBAN cards with clips

To sum up, the Kanban method is based on 4 fundamental principles:

- Start by doing what we're doing now: As the Kanban method is fairly flexible, it can easily be integrated into any process or flow already in place and will be optimised thanks to the principle of continuous improvement.

- Agreeing to implement progressive changes: It is essential that the team decides to accept the changes made gradually, at the risk of creating discontent if the changes are too abrupt.

- Respect and commit to the current process, roles and responsibilities: To avoid disrupting the teams, it will be necessary to respect the roles and responsibilities of each person, using a methodology and effective management.

- Encourage initiative and leadership at all levels: Whether for employees or senior managers in an organisation, all acts of leadership should be encouraged.

SESA SYSTEMS offers you a wide range of products related to the KANBAN planning method, as well as a Kanban Guide to go into the subject in greater depth, providing you with a great deal of additional information for implementing your Kanban methods.